The testing machine is mainly composed of a main machine, a microcomputer control unit, a strong current control unit and test accessories.

1. Main uses:

The test machine is mainly used for radial load fatigue test of motorcycle, moped and other passenger car wheels.

Implementation standards:

QC/T211-1996 "Test method for light alloy wheels of Motorcycles and mopeds"

QC/T212-1996 "General Technical Conditions for aluminum alloy integral wheels for Motorcycles and mopeds"

JASO T 203-85 "Motorcycle Light Alloy Wheels"

Iso 8644-1988 "Motorcycles - Light alloy wheels - Test methods"

Iso 8645-1988 "Mopeds - Light alloy wheels - Test methods"

GB/T6147-92 "Testing machine packaging, packaging marks, storage and transportation technical requirements"

2. Main technical specifications:

1, the maximum test force: 10KN, indicating accuracy from 20%FS ±1%

2, drum surface linear speed: greater than 120km/h

3, drum diameter: 1707.6mm±0.25

4, drum width: 400mm

5, show the cumulative number of tests and test mileage: 10

6, measuring wheel hub range: maximum 800mm (including tires)

7. Total motor power: 45kw

8, speed and speed measurement accuracy: ±1%

9, drum radial runout: ≤0.2mm

10, show the number of tests: 6

11, speed and force display: 4 and above

3. Functional characteristics of testing machine:

The testing machine is mainly composed of a main machine, a microcomputer control unit, a strong current control unit and test accessories.

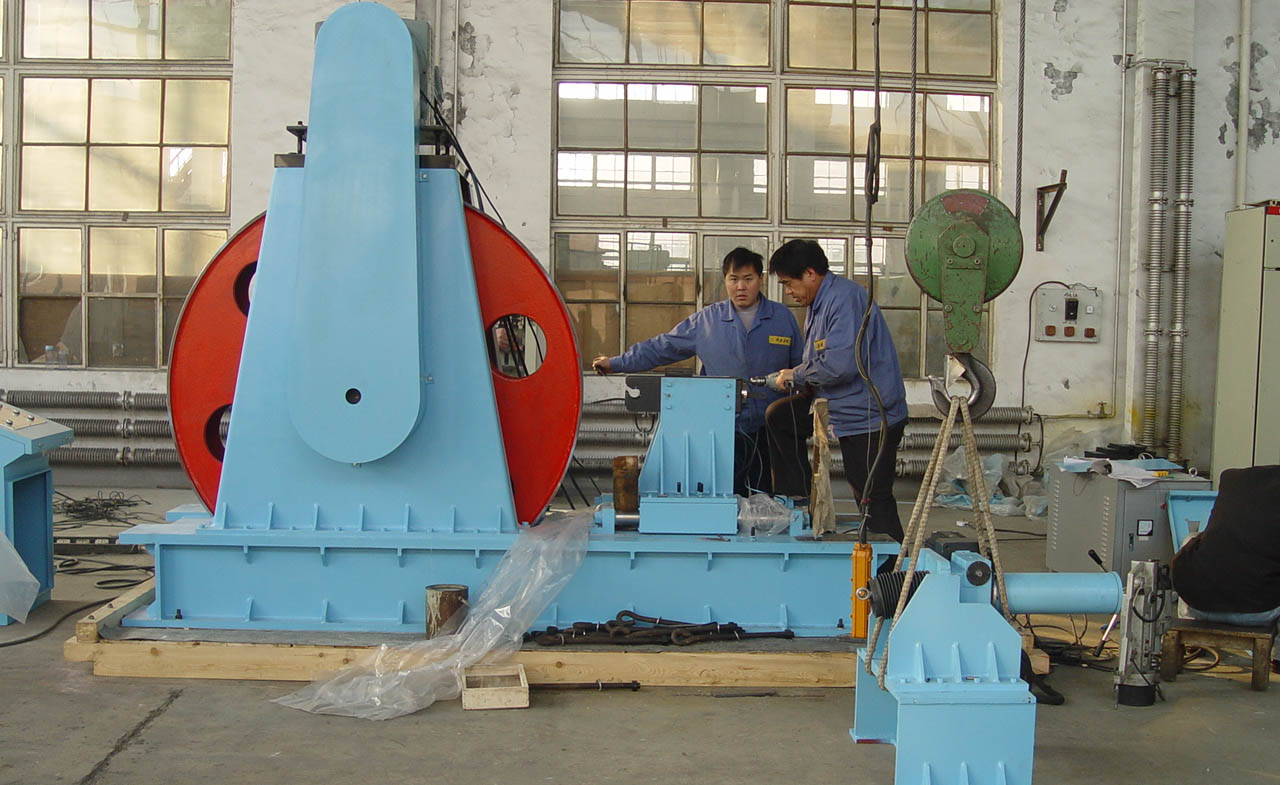

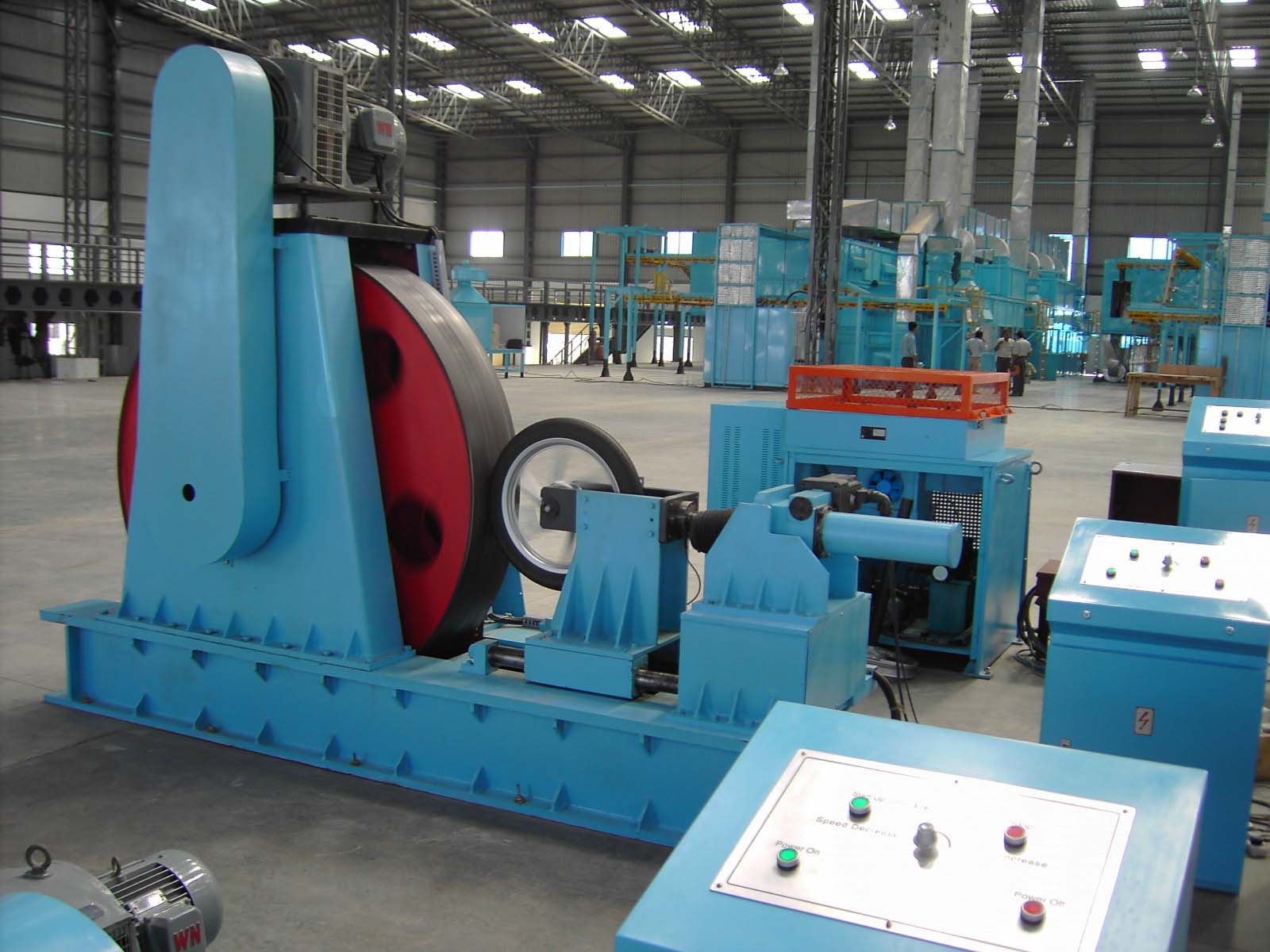

The main machine adopts welding structure design and manufacturing, horizontal loading design, large drum adopts international standard design, the design diameter of 1707.6mm, as far as possible to simulate the road condition, excitation speed regulating motor to drive the drum to achieve stepless speed regulation, to realize the test of different driving speeds, loading bracket adopts low-damping linear element transmission, servo motor drive closed-loop control. The load sensor completes the measurement of applied load, so as to realize the closed-loop control of fatigue test load and the emergency shutdown function of fatigue damage.

The test process is automatically controlled by the computer. After the test load and test mileage are set by the computer, the computer automatically controls the servo motor to load and automatically stops when the test mileage is reached.

Computer control system with safety protection, overload, tire, wheel damage and other accidents can be automatically unloaded and shut down.

Equipped with strong current control box, complete the drive control of excitation speed regulating motor, with power on, off, motor start, stop, speed increase or decrease and other operation functions.

Microcomputer control unit, configuration computer, computer for Lenovo brand machine, mainstream configuration, computer built-in signal amplification A/D conversion board, complete sensor signal amplification and signal analog-to-digital conversion, computer software for WINDOWS platform software, with test parameter setting, dynamic test waveform display, test data storage, output test report and other functions.

The printer prints the test report.

4. Main configuration

1. A welded main frame

2. Load a servo motor

3, a servo control system

4, a set of loading mechanism

5. One exciting speed regulating motor

6. Turn one hub

7, a load sensor

8. One set of electric control cabinet and strong current control part

9. A computer

10, a set of test software

11. A printer

12, a set of wheel installation fixture

5. Acceptance, installation, commissioning and training

1. Acceptance

(a) The pre-acceptance of the equipment shall be carried out at the Seller's site, and the seller shall arrange delivery after the parties confirm that the pre-acceptance is qualified. The final acceptance shall be carried out at the buyer's site. If the pre-acceptance conditions are met, the final acceptance shall be qualified. Both parties shall sign the acceptance report.

(b) Acceptance criteria: The acceptance of equipment shall be based on this technical agreement signed by both parties.

(c) The seller shall issue to the buyer the packing list, instruction manual, certificate of qualification and other materials of the equipment.

2. Installation and debugging

The Seller shall be responsible for the transportation of the equipment at the Seller's expense. After the equipment arrives at the Buyer's site, the Buyer shall be responsible for unloading and positioning the equipment, and the seller shall provide necessary guidance. Installation, wiring and commissioning shall be the responsibility of the seller. The Buyer shall provide necessary and appropriate assistance to the seller's personnel during the Buyer's debugging.

3. Personnel training

When the equipment is accepted by the Buyer, the seller shall provide free technical training (for 1 day) to the operator, technical personnel and equipment maintenance personnel of the buyer, so that they can achieve the ability of independent and safe operation, adjustment and use, daily maintenance and quick troubleshooting; The seller requires the buyer to have the corresponding quality of the above-mentioned personnel.

6. Quality assurance

The equipment shall be deemed to have been officially delivered only after the seller's acceptance on site. The equipment three contract period is one year from the date of formal delivery. During the period of three guarantees, the seller shall provide free maintenance services for all kinds of equipment failures in time. For all kinds of parts damaged by non-human causes, timely and free replacement. If the equipment fails during use outside the warranty period, the seller shall provide timely service to the buyer and actively assist the buyer in completing the maintenance task.