ND3500 series dynamic and static test system is a torsion series product developed on the basis of the original DT1000 series.

1. Product introduction

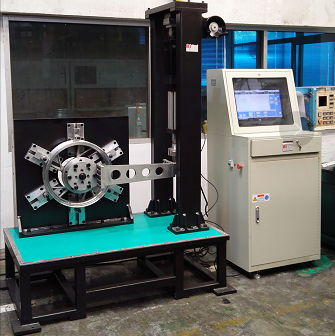

ND3500 series dynamic and static test system is a torsion series product developed on the basis of the original DT1000 series. In addition to retaining the original tensile and compressive fatigue function, the newly added torsion fatigue function realizes the long-cherished wish of tensile and compressive fatigue and torsion fatigue in one machine.

This series of products is suitable for the dynamic and static mechanical properties of materials and small parts, including tensile, compression, torsion, low cycle and high cycle fatigue tests of materials and parts. High and low temperature mechanical test can be carried out with high and low temperature chamber.

The development and development process of servo dynamic and static universal testing machine series adopts the development and manufacturing experience of internationally famous servo dynamic testing machine companies, adopts the development concept of "unization, modularization and standardization", absorbs the international advanced servo dynamic testing machine technology, and combines the actual use of domestic users. The key supporting components of the servo dynamic testing machine are selected from famous brands of similar international and domestic products. The stability and reliability of the system are greatly improved, the key units and components of the system are manufactured with today's international advanced technology, and the overall performance of the whole test system is equivalent to the technical level of the internationally famous dynamic testing machine company. This series of products has the characteristics of easy to use, high control precision, good reliability and so on.

2. Meet the criteria:

QC/T211-1996 "Test method for light alloy wheels of Motorcycles and mopeds"

GB/T22435-2008 "Motorcycle and Moped Light Alloy Wheels"

Iso 8644-2006 "Motorcycles - Light alloy wheels - Test methods"

GB/T6147-92 "Testing machine packaging, packaging marks, storage and transportation technical requirements"

JASO T 203-85 "Motorcycle Light Alloy Wheels"

3. Biggest advantage:

1. Energy saving (conventional single 220V power supply, the whole machine power is small), environmental protection (no oil, no water and no odor).

2. Corresponding tooling can be interchangeable, reducing the cost of use.

3 More convenient and flexible operation, more user-friendly.

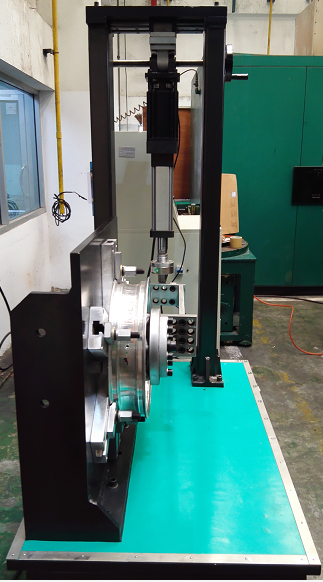

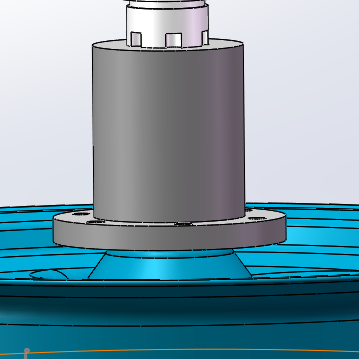

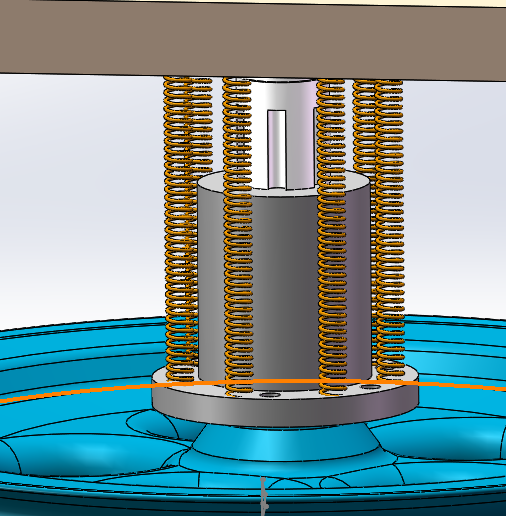

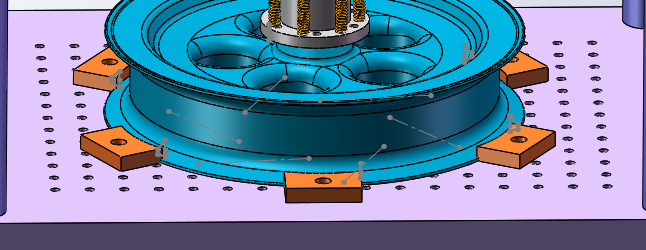

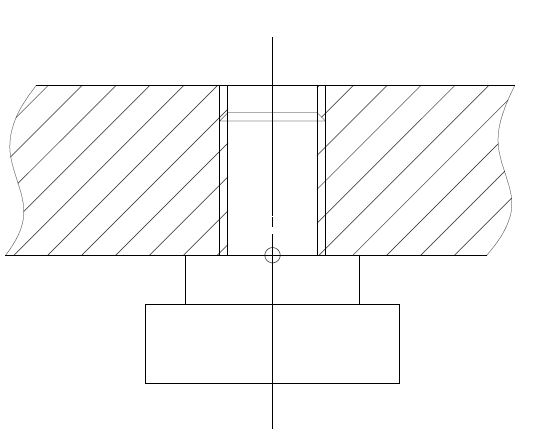

4 specimen in the test process is not subject to additional external force, the structure of the horizontal structure, independent output shaft through the spline sleeve and hub connection, for the hub, no force except torque is applied, hub connection sleeve through the spline form and shaft connection, so as to ensure that the sleeve and shaft can be relatively sliding, there is enough strength to ensure that the mechanism has enough strength to drive the hub. As shown in the picture;

5. Install the lifting spring to eliminate the excess force exerted on the wheel hub by the axle sleeve due to its own weight.

As shown below: (Minimize external forces)

4. Software Introduction:

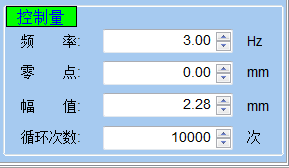

1. The software is easy to operate: just create a new test, enter the test control amount, and click Start test

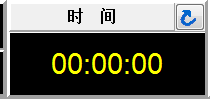

2. With a time countdown, clear test completion time

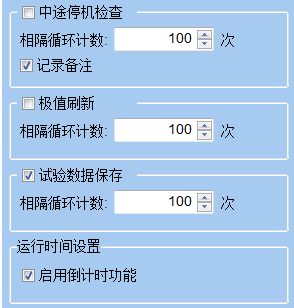

3. With stop check function, you can set the number of stop check and record data

5. Program description:

ND3500 series dynamic and dynamic test system is mainly composed of a main machine (upper servo linear actuator), locking positioning shaft, locking press plate, transverse fine adjustment, swing arm and its drive module, full digital single-channel servo controller, computer printer, related test software, other necessary accessories.

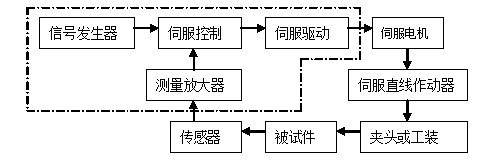

See the attached diagram for working principle and control block diagram

System working principle diagram

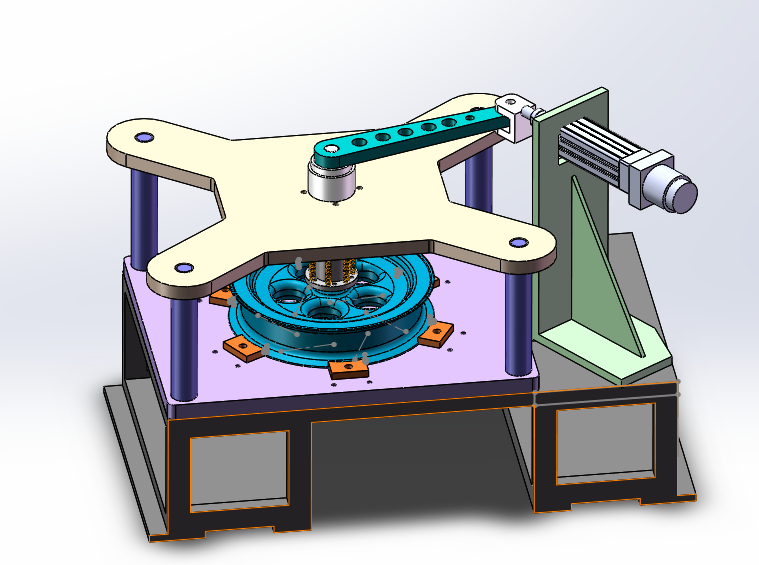

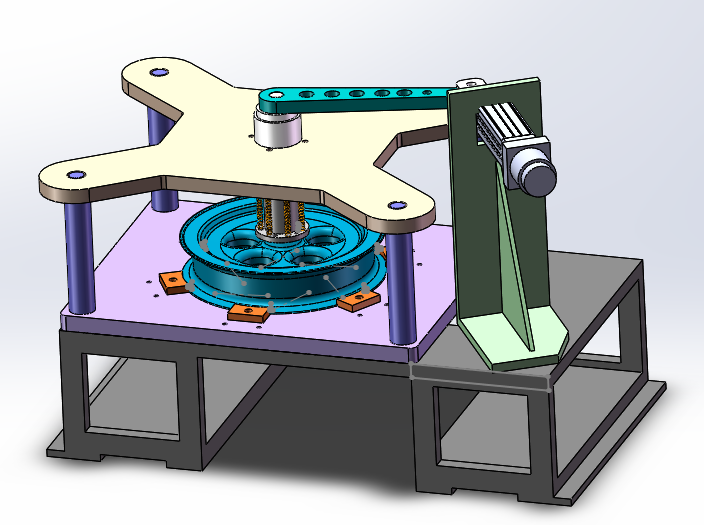

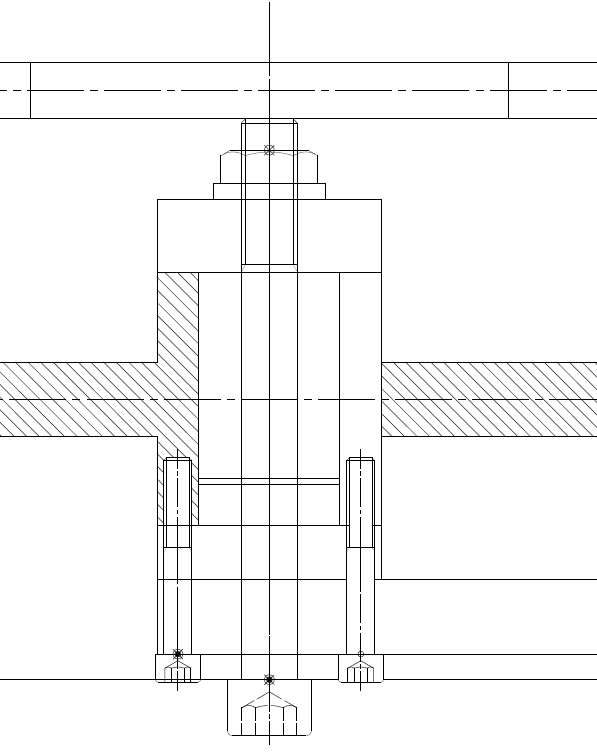

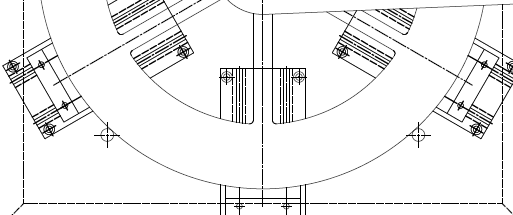

1, host: the host is a frame type structure, the servo linear actuator is placed inside the host frame. The swing arm is automatically positioned by the hub bolt, and then the swing arm is locked with the hub by a special screw, and the contact surface with the hub is processed by krulling to ensure that there is no relative rotation between the swing arm and the hub during the test (the corresponding tooling and locking shaft size will be consistent with the original tooling), as shown in the figure:

The actuator is hinged with the swing arm, and the swing arm is hard linked with the hub, so that the linear motion of the actuator will be converted to the rotation of the hub when it is working, so as to achieve the twisting function of the hub. When clamping the hub, the relative position of the swing arm can be adjusted according to different thicknesses. The bottom of the actuator is equipped with an adjustment screw, which can be adjusted accordingly with the position of the swing arm. Ensure that the actuator is perpendicular to the swing arm to extend the service life of the corresponding parts. The upper and lower height of the actuator is adjustable, which can make the actuator in different positions and increase the service life of the actuator.

2. Tooling: 1) Positioning, as shown in the picture

(Tooling and slide table diagram)

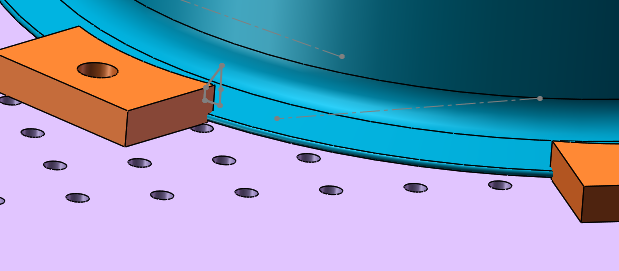

The porous table is used to support the hub end face, and the sliding table is equipped with a movable arc positioning block (the position can be changed according to different hub diameters, the estimated hub diameter can be drilled in advance, and the position can be adjusted when it needs to be replaced).

(Wheels of different diameters are configured with circles of corresponding diameters)

After the hub is fixed to the rotation, the positioning block is pushed to the edge of the hub along the respective guide slots and locked.

2) Wheel hub locking: as shown in the picture

Locking device adopts the most reliable clamping plate, M20 bolts with special nuts to ensure the reliability and convenience of the test, the clamping device is common with the original equipment,

3) In addition to meeting the torsion test, the addition of tooling can be extended to the tensile fatigue test of the material.

6. Actuator characteristics

1, can work in harsh environment, waterproof, explosion-proof, salt spray and so on.

2, using high precision lead screw and famous motor, high positioning accuracy, fast response, adjustable stroke and speed.

3, this product low noise, energy saving and environmental protection, long working life.

4, this product is small in size, light in weight, easy to install and debug operation.

5, this product is equipped with over current, over stroke and other protective measures to ensure the safe operation of the equipment.

[Main performance indicators]

Rated dynamic pushing force: 0-5KN

Action frequency (Max.) : 15 times/SEC

Rated stroke: 0-100mm

The speed is 0-500mm/s

Working environment: high temperature resistance, dustproof, waterproof, explosion-proof

Ambient temperature: -40℃ ~ 60℃

Relative humidity: 80% (20±5℃)

Motor power: 3KW(Panasonic or Fuji)

[Functional features]

1, fast acceleration, short positioning time, good dynamic performance! (Precision, precision, fast, stable)

2, precision, strong

3, can be used in a single axis

4, can be used for multi-axis combination

5, modular application

6, simple structure, can save mechanical design space

7, with a variety of installation and connection methods and accessories for design choice

8, can be matched with a variety of motors and motor control regulator

9, can be multi-point positioning and multi-section control

10, the selection of appropriate accessories, can improve the assembly efficiency

11, to meet the design of different accuracy requirements

12, save time, easy maintenance

7. Full digital single channel servo controller:

1, the number of control channels: 1, including test force, test displacement, test deformation three closed loop control loop, with control mode smooth switching function without disturbance. The maximum closed-loop control data refresh frequency is 2kHz; The resolution of controller A/D and D/A is 14 bits. Signal frequency range: 0.001Hz ~ 5Hz; Signal generator waveform: sine wave, triangular wave, etc. The controller has the function of limit parameter setting and complete protection function. In addition to overload (110%) protection and secondary overcurrent protection, it also has arbitrary dynamic load protection, static load protection, frequency protection and so on.

2, servo dynamic testing machine (system) control software:

System Management Software: The software is the basis of the whole digital servo controller, its main functions are to manage the hardware resources of the control system, define the sensor, adjust the digital control parameters, set the protection, display the current control mode, hydraulic and function generator status and sensor calibration. The dual trace digital oscilloscope, digital servo valve ammeter and 6 digital voltmeters are provided for real-time display of test data. Function generator software: The software is mainly used for constant amplitude dynamic test, such as constant amplitude fatigue test. The function generator software will automatically track and correct the peak and valley values of the control quantity (such as load) to ensure that the typical dynamic error value of each peak is ±1%FS during the whole test process. During the test, the operator can dynamically change the peak, valley and frequency, and can also perform manual or automatic signal holding. If the automatic signal holding cycle interval is set, Each time the number of test cycles is increased by one cycle interval, the software will automatically maintain the signal at a set level to facilitate the measurement of some test data (such as visual crack length). The software optional waveforms are sine wave, triangular wave, oblique wave, sawtooth wave, combined wave, combined oblique wave test. At the end of the test, the software will save some important data, such as test load, frequency, number of cycles and test time. The software can also perform simple static tests. Multifunctional test software: The software is a flexible, fully functional test software, users can use it to design special test methods, but do not need programming. This software has a variety of control functions, data acquisition functions and other auxiliary functions of the servo controller are done on a panel in the form of ICONS, users can drag and drop these function ICONS into the test definition panel with the mouse, and combine them according to user needs at will, you can test according to user-defined test methods. The software can be used for random spectrum test.

3, controller technical parameters:

3.1 All-digital general signal conditioning unit: test force, displacement, Angle three closed loop control loop. It has control mode smooth switching function without disturbance.

3.2 The maximum closed-loop control data refresh frequency is 5Hz.

3.3 The resolution of controller A/D and D/A is 16 bits.

3.4 Signal frequency range: 0.01Hz ~ 10Hz.

3.5 Signal generator waveform: sine wave, triangular wave, program wave.

3.6 Control accuracy: the static control accuracy is 0.5% FS, and the typical dynamic control accuracy is 1% FS.

3.11 Limit Parameter Setting Function.

8. Other configuration and necessary accessories:

1 Corresponding fixture tooling

2 Spare screw

3 Data backup optical

4 Configuration of torsion fixtures;

9. Main technical performance indicators:

1. Maximum torque: 3500NM

2, the maximum amplitude of the actuator: ±50mm, indicating accuracy of ±0.5%FS.

3, frequency range: 0.1-5Hz (the highest frequency corresponds to the maximum amplitude ±1)

4, the maximum line speed 500mm/s

5, control mode: load, displacement, deformation control mode, the main test waveform: supported by the controller (including sine wave, triangular wave, oblique wave and external input waveform);

6, the software zero complete display hysteresis curve.

7. Maximum test space: 450mm (including chuck).

8. Distance between columns: 450mm. (to be confirmed)

9, measured wheel diameter: 10-24 inches, wheel width of 8 inches

10, test force arm: 700±1mm

11. Machine weight: ≈1500kg

10. System configuration list: See attached table

| Item Name | Quantity | Origin/brand | ||

| 1 | Host | frame (including column, beam, workbench, etc.) | 1 | self-made |

| Servo linear actuator | 1 | self-made | ||

| Servo system | 1 | domestic | ||

| Load sensor | 1 | American World Bolt | ||

| Server and motor | 1 | Panasonic Japan | ||

| Hub fixing fixture | 1 | self-made | ||

| Locking clamp block | 6 | self-made | ||

| 2 | Full digital servo controller | 1 | domestic | |

| 3 | Test the application software package | 1 | self-made | |

| 4 | Computer | 1 | HP | |

| 5 | A4 Printer | 1 | HP | |

| 6 | Signal cables and connection cables | 1 | self-made | |