The metal wire torsion testing machine is suitable for measuring the ability of metal wire with a diameter (or characteristic size) of 3-5.0mm to withstand plastic deformation in unidirectional or bidirectional torsion and showing the defects on the surface and inside of the wire.

1. Main use

The metal wire torsion testing machine is suitable for measuring the ability of metal wire with a diameter (or characteristic size) of 3-5.0mm to withstand plastic deformation in unidirectional or bidirectional torsion and showing the defects on the surface and inside of the wire.

2. Principle

Unidirectional torsion: The sample rotates 360 degrees evenly around its axis in one direction as a single torsion to the specified number of times or the sample breaks.

Two-way torsion: the sample rotates 360 degrees evenly around its axis in one direction as a torsion to the specified number of times, and then rotates the same number of times in the opposite direction or the sample breaks.

Metal wire torsion testing machine applicable standards:

The metal wire torsion testing machine is suitable for the People's Republic of China standard GB/T 239.1-2012 "Metal wire Part I unidirectional torsion test method", GB/T 239.2-2012 "Metal wire Part II bidirectional torsion test method", It also applies to the international standards ISO 7800:2003 "One-way torsion test method of metal wire" and ISO 9649:1990 "two-way torsion test method of metal wire".

Metal wire torsion testing machine application field:

The machine is mainly used in colleges and universities, scientific research departments, industrial and mining enterprises mechanics laboratory of metal wire mechanical properties analysis, but also widely used in production units online testing; The main industries are steel high-speed line, prestressed steel wire factory, quality supervision, scientific research institutes, road traffic, construction industry, steel wire rope, wire and cable, electrified railway with copper and copper alloy wire, copper contact wire and other production and use departments.

Metal wire torsion testing machine host introduction:

1) Mechanical structure:

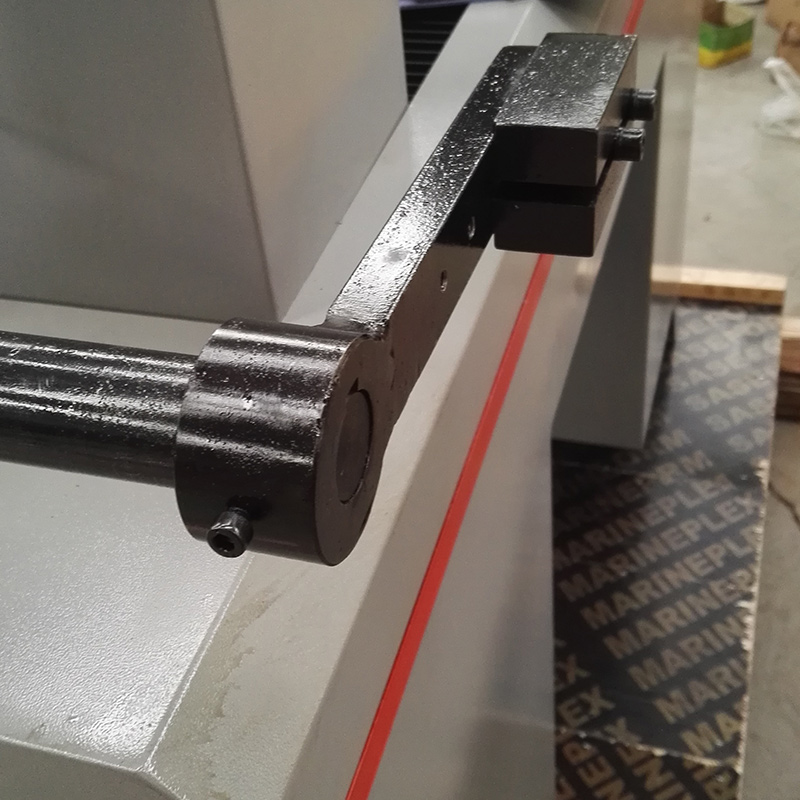

The model uses high-performance AC motor as the power output, with high-precision deceleration motor, so that the power can be stable output. The motor is driven by highly reliable and stable frequency converter, which improves the smoothness of the machine operation and reduces the power consumption. One chuck is fixed on the motor output shaft, and the other chuck is fixed on the movable bearing seat. The moving seat adopts linear bearing, which has low friction resistance and ensures the flatness of axial movement. The axial tension force is applied by a weight, and the force is applied to the wire by a 10:1 L-shaped lever.

2) Control unit:

The control system adopts imported Atmel microprocessor, combined with mature control method, so that the control unit can be guaranteed in terms of control accuracy and operation stability. The industrial LCD screen is selected for display, which has the characteristics of long life, stable performance and wide viewing Angle. The counter is a Hall sensor with strong anti-interference ability. The counter also has high sensitivity and better dynamic performance. The machine has the function of automatically judging wire breakage

Metal wire torsion testing machine technical indicators:

| Model | EZ-5 |

| Working Mode | Automatic Loading |

| Display Mode | LCD Chinese character menu display |

| Parameters: | |

| 1. Clamping metal wire diameter range | 3.0≤d(D) < 5.0 |

| 2. Space between the two fixtures | 500mm |

| 3. Clamp range | 3.0-5.0mm |

| 4. Twisting speed | 30, 60r/min |

| 5. Speed error | <±10% |

| 6. The minimum reading value of the number of turns | 0.1 |

| 7. The testing machine size (length * width * height) | 1250×430×600mm |

| 8. The weight of the testing machine (net weight) | 140kg |

| 9. Power supply | AC220V 50 Hz |

| 10. Noise | <70 dB (A) |

| 11. Assembly quality | Meets the national standard GB/T2611 |

| 12. Packaging, transportation | In line with the Ministry of machinery standards JB/T6147 |

| List with machine | |

| 1. Tools and weights | 1 set |

| 1. Technical data | 1 copy |

More metal wire torsion testing machine information please contact us Jinan Beacon Automation Equipment Co., LTD. Professional production of hydraulic universal testing machine, fatigue testing machine, torsion testing machine, high temperature creep testing machine, spring testing machine, bending testing machine, impact testing machine, bending strength testing machine, tensile strength testing machine and so on.