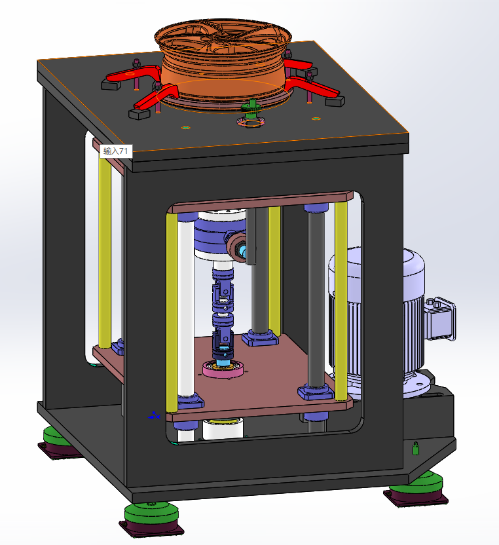

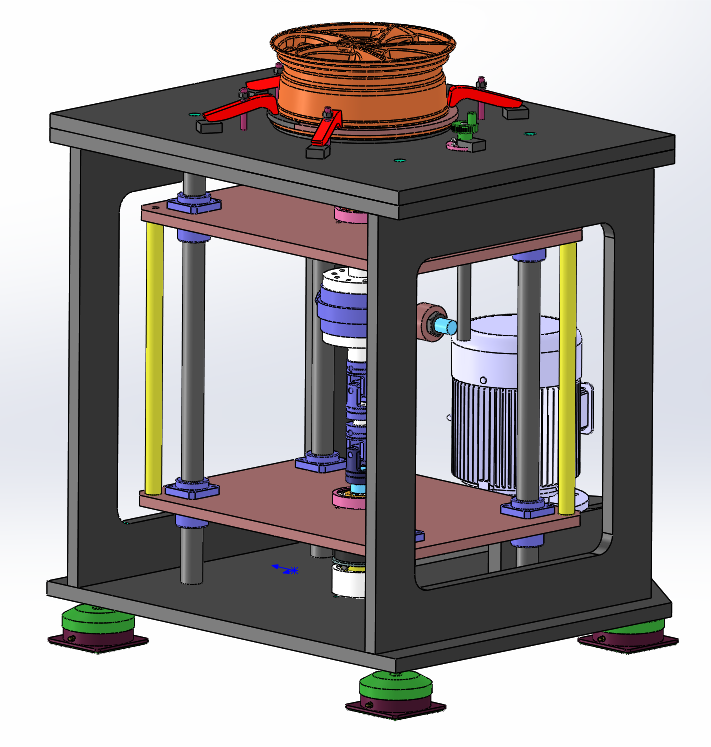

It mainly simulates the turning of the car in the state of load, detects the inner and outer diameter of the hub and the fatigue resistance of the hub link point. The fixture design is provided in accordance with the test wheels supplied by the customer.

1. Product Introduction:

-50000 microcomputer controlled locomotive wheel bending fatigue testing machine is mainly suitable for wheel bending fatigue test. We are committed to the development and production of wheel testing equipment, automobile wheel bending fatigue testing machine is the conventional equipment for automobile wheel testing. It mainly simulates the turning of the car in the state of load, detects the inner and outer diameter of the hub and the fatigue resistance of the hub link point. The fixture design is provided in accordance with the test wheels supplied by the customer.

2. The equipment is mainly based on standards:

SAE J267-2014

GB/T 5334-2005 Passenger car wheel performance and test methods

QC/T211-1996

QC/T212-1996

ISO8644-2006

GB/T22435-2008

JASOT203-2005

GB/T6147-92

At the same time, it can also meet the standards provided by users: such as Harley, Yamaha, Honda, Italy Biggio

3. Product functions:

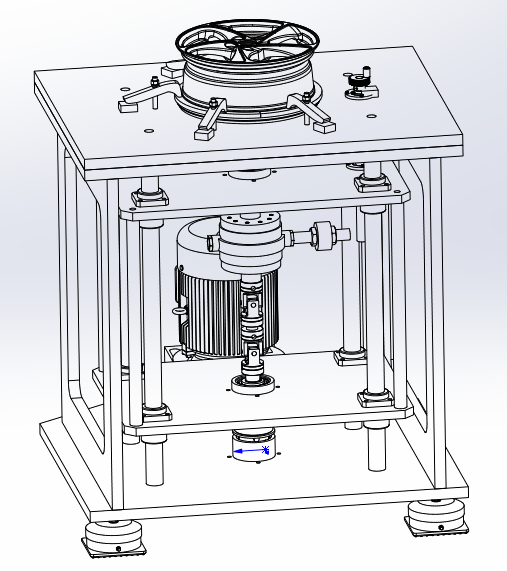

1. The testing machine is mainly composed of a host, parameter measurement display unit, strong current control unit, test with centrifugal force measurement system.

2. The main machine is made of casting structure, the sample is easy to install, the wheel does not rotate, the load rotates

3. The applied torque measured by the relationship between load and speed can greatly save the test energy consumption.

4. The driving power adopts variable frequency speed regulating motor to achieve stepless speed regulating, which drives the load to rotate at high speed and exerts the bending moment on the wheel of the rotating shaft.

5. The test detects the bending of the spindle during the test, so as to achieve the emergency stop function of the wheel damage.

6 Centrifugal force sensor as a force acquisition source, high-speed acquisition, multi-channel division.

7. The measurement control software has the following main functions;

1) Test parameters are set by software;

2) The software displays test graphics, loading force values, etc

3) Report printing; Document management; Load calibration;

Detailed description is as follows:

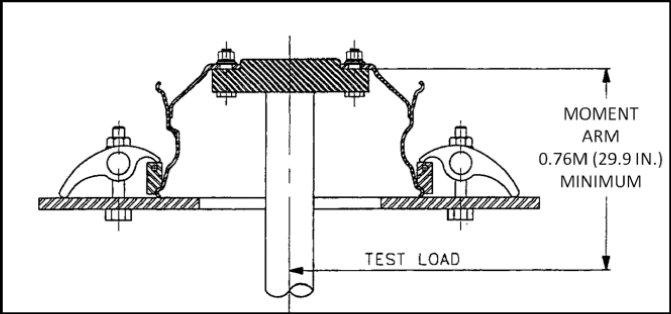

1. Moment closed-loop adjustment

2. The bending moment and displacement resonance circle are displayed on the X-y coordinate system of the screen

3. Speed adjustment, load change number count (stop and shut down count keep) test parameters stop and shut down keep

4. The preset loading arm maximum displacement limit value monitoring, can input/display the following parameters; Bending moment set value/bending moment measured value

5. The initial offset of the lever, the instantaneous value of the offset of the lever, the limited value of the offset increment of the lever (as the shutdown regulation), and the test speed

6. With safety protection functions and facilities, safety protection door can not be tested when opened, the test has a safety alarm prompt function; The number of revolutions can be set, and the machine will stop automatically when the specified number of revolutions is reached;

7. Configure the strong current control box to complete the drive control of the motor.

8. Microcomputer control unit, industrial control computer, computer built-in signal amplification A/D conversion integrated board, to complete the sensor signal amplification and signal analog-to-digital conversion,

9. The computer software for WINDOWS platform software, with dynamic display, storage, output test report and other functions.

10. Other electrical components are all imported international well-known brands.

4. Product parameters:

1. The test bending moment range: 10 ~ 800 N·m stepless adjustable, measurement and control accuracy ± 1%.

2. The test maximum speed range :50-800r/min, stepless frequency conversion speed regulation, accuracy: ± 1%.

3. The test wheel diameter: φ125-φ590, wheel width: 4 "~12".

4. Total motor power: 5.5KW.

5. Display the test speed and the cumulative number of tests: 1.0×10r, automatic unloading and stop when it reaches the set value.

6. Speed regulation: frequency conversion closed-loop speed regulation.

7. Loading mode: wheel does not turn, load rotation.

8. Bending moment sensor: 20 kN·m

9. Loading mode: closed-loop loading

10. Loading point offset measurement accuracy: ± 2.5%

11. Loading lever: 670 mm

12. Sampling point: 500 points per week (tentative)

13. Imported high-precision laser ranging sensor detects the deformation of the loading rod

14. Wheel connecting disc bolt hole position: less than 0.06mm

15. The overall dimension of the host is about: length 1.2m× width 1.2m× height 1.2m

16. Equipment weight: about 4t

Product configuration:

| Serial Number | Name | Quantity | Manufacturer Technical | Specifications |

| 1 | main engine vertical rack | 1 | Jinan AAA | wheel non-rotating |

| 2 | Variable frequency motor | 1 | ABB | 7.5kW |

| 3 | Variable frequency motor speed regulating device | 1 | Domestic | Delta |

| 4 | Independent revolution recording device | 1 | Self-developed | |

| 5 | Computers | 1 | Hp | mainstream configuration |

| 6 | printers | 1 | HP | HP A4 laser printer |

| 7 | pairs of central devices | 1 | Jinan AAA | sensor American Shiquan |

| 8 | Loading device | 1 | Jinan AAA | |

| 9 | Fixture | 1 | Jinan AAA | |

| 10 | Software | 1 | Jinan AAA | |

| 11 | Electric control cabinet | 1 | Jinan AAA | |

| 12 | Bending moment sensor | 1 | Jinan AAA | X-Y(North latitude sensor) |

| 13 | Closed loop control system | 1 | Jinan AAA | SED5220 |

| 14 | Loading lever | 1 | Jinan AAA | |

| 15 | High precision laser ranging sensor | 2 | Imported | AK-MS15 |

Use environment:

1. Environmental requirements

1) Laboratory temperature requirements: 25±5℃

2) The installation level should not exceed 0.2/1000

3) The relative humidity of the laboratory should be ≤75%; In a vibration-free environment;

4) in the surrounding environment of non-corrosive media;

5) in the surrounding environment without obvious electromagnetic field interference;

6) The equipment comes with cushion, no need to build foundation.

2. Energy requirements

1) Power supply: Power supply (three-phase) AC 380 V± 10%, single-phase voltage 220 V± 10%

2) Power frequency: 50 Hz± 2%

3) Compressed air supply pressure: 0.4 ~ 0.6MPa

4) Maximum power consumption: 8kW