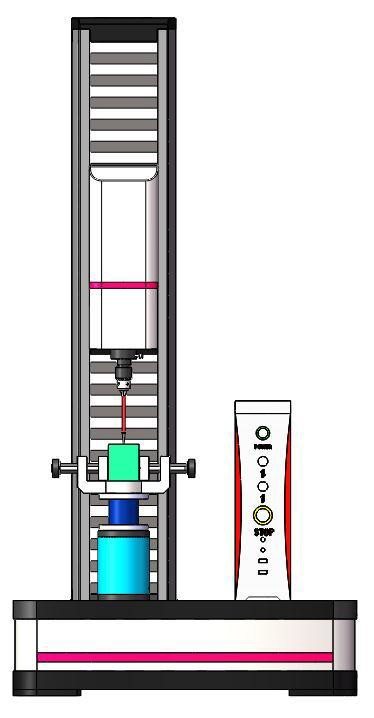

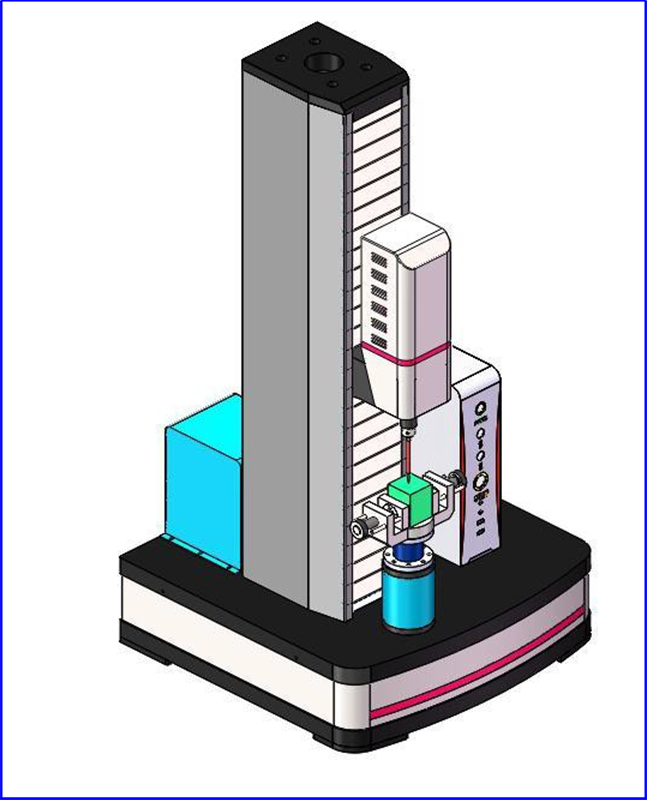

TN5005 tensile torque testing machine adopts column frame structure, tensile pressure and torque are tested in the frame at the same time, the two channels are used separately, tensile pressure is loaded by servo electric lead screw.

Main functions of the equipment:

TN5005 tensile torque testing machine adopts column frame structure, tensile pressure and torque are tested in the frame at the same time, the two channels are used separately, tensile pressure is loaded by servo electric lead screw, torsion is loaded by servo motor reducer and dynamic torque sensor, tensile torque testing machine is mainly used for non-metallic materials, small force value structural parts, rubber bottle stopper, and so on. The system can also be operated in a single axis, and the corresponding tensile or torsion experiments can be carried out.

The whole structure adopts column type frame structure, which is composed of column, sliding table, middle moving cross beam, tensile pressure loading, torsion loading, and upper connecting auxiliary top beam.

The tension and torsion experiment can be tested separately or simultaneously, and the two can not be coupled in the experiment.

The space adjustment is adjusted by the lead screw of the drawing end, and the electric control is easy to operate.

The cross beam movement and emergency stop operation buttons are placed next to the main engine, which are convenient for the tester to operate;

The equipment adopts unitized, standardized and modular design, which has the characteristics of low damping, high response, high life and no gap design.

Suitable for static tension/tension/tension/torsion/torsion test;

Rated test force +/-1kN, total stroke 250mm;

Rated torque +/-5Nm, unlimited torque Angle;

Suitable for long-term static loading test;

Displacement sensor, load sensor, torque sensor Angle sensor with force, displacement torque Angle closed-loop control loop;

The compression and torsion composite sensor is placed on the upper part of the workbench, and the corresponding tooling can be connected to realize different experiments;

Reference fixture (as shown below)

Technical parameter requirements:

1. Maximum size: 550mm× 520x1150mm

2. Stretching space: 0-250mm

3. Torsion range: 0~9999 degrees (unlimited)

4. Drawing speed range: 0.01-500mm/min

5. Twisting speed range: 0.01-720 degrees /min

6. Push-pull rated test force: ±1000N, accuracy ±1%, accuracy range 2%-100% FS.

7. Torque rating: 5N.m, accuracy ±1%, accuracy range 2%-100% FS.

8. Control mode: closed-loop control;

9. Tension, pressure display: computer control tension or pressure loading, software real-time display

10. Torque display: computer control torsion loading, real-time display torque, Angle

11. Experimental environment: 25±3℃, humidity: 50RH%

12. Protection device: limit protection, tensile limit protection, torque limit protection

13. Clamping method: mechanical locking

14. Machine weight: about 70kg

15. Working power supply: 220AC, 50HZ

16. Frequency range: 0.001-2Hz. (low week)

17. Controller type: single channel, displacement and force two closed-loop channel.

18. Main test waveforms: sine wave, triangular wave, rectangular wave, oblique wave, etc.

Control system:

Supertest two-channel full digital hydraulic servo controller and software system to achieve full digital closed-loop control of the testing machine.

1. Main technical indicators of full digital two-channel hydraulic servo controller

Number of control channels: 2.

Each channel includes three closed-loop control loops of test force (torque), displacement (Angle) and strain, and has the function of smooth switching of control mode without disturbance.

Configure the number of site control interfaces: 2.

Three all-digital universal signal conditioning units: test force (torque), displacement (torque), strain three closed-loop control circuits. It has control mode smooth switching function without disturbance.

The resolution of controller A/D and D/A is 16 bits.

Control accuracy: The relative accuracy of static control is better than 1% FS.

Other necessary I/O input and output units: four analog inputs, four analog output interfaces; Four digital input, four digital output interface.

Limit parameter setting function.

2. Testing machine (system) control software Supertest3.0:

2.1 System management software simttest3.0: This software is the basis of the whole digital servo controller work, its main functions are to manage the hardware resources of the control system, define sensors, adjust digital control parameters, set protection, display the current control mode and function generator status and sensor calibration.

2.2 Multi-functional test software Supertest3.0: This software is a flexible, full-function test software, users can use it to design special test methods, but do not need programming. This software has a variety of control functions, data acquisition functions and other auxiliary functions of the servo controller are done on a panel in the form of ICONS, users can drag and drop these function ICONS into the test definition panel with the mouse, and combine them according to user needs at will, you can test according to user-defined test methods. The software can be used for random spectrum (a combination of different experimental processes) tests.

2.3 Control System

The full digital closed-loop measurement and control system has many advanced characteristics and technological innovations, mainly reflected in:

1. Realized four kinds of closed-loop control of test force, sample deformation, beam displacement and test process;

2. The data acquisition system consists of 4 high-precision 24-bit A/D conversion channels. The highest resolution is 1/300000, the whole process is not divided;

3, Choose BB, AD, Xilinx and other original brand integrated devices, all digital design;

4, in line with PCI bus standards, microcomputer automatic identification and installation, so as to "plug and test";

5, electronic measurement system without analog components such as potentiometers, to ensure interchangeability, easy maintenance and replacement.

Software interface

Parts list:

| Item | Name | Specifications | Model | Quantity |

| 1 | Host loading rack | 1KN | 1 | autonomous |

| 2 | screw | 2510 | 1 | Taiwan TBI |

| 3 | Linear guide rail (1 slider) | 30 | 2 | Huayin |

| 4 | Servo motor | 1500W | 2 | Panasonic |

| 5 | Two component force sensor | 1KN/5Nm | 1 | custom |

| 6 | Torque test | 200N.m | 1 | autonomous |

| 7 | Servo motor | 1500W | 1 | Panasonic |

| 8 | Precision reducer | P60/5/750 | 1 | Troda |

| 9 | Pull and pressure measurement and control system and software | 1 | autonomous (software main interface plus remarks window) | |

| 10 | Torsion measurement and control system and software | 1 | autonomous (software main interface plus remarks window) | |

| 11 | Control cabinet (weak current control) | 1 | autonomous | |

| 12 | tooling | pneumatic three-jaw chuck | ||

| 13 | Documents | Operation instructions, software instructions, certificates, etc | ||

Adhesive Stripping 90 Degree Stripping Testing Machine

Adhesive Stripping 90 Degree Stripping Testing Machine

Wire Twisting And Winding Integrated Machine

Wire Twisting And Winding Integrated Machine

Adhesive 90-Degree Peel Strength Testing Machine

Adhesive 90-Degree Peel Strength Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

CPU-1020 Cup Convex Testing Machine

CPU-1020 Cup Convex Testing Machine