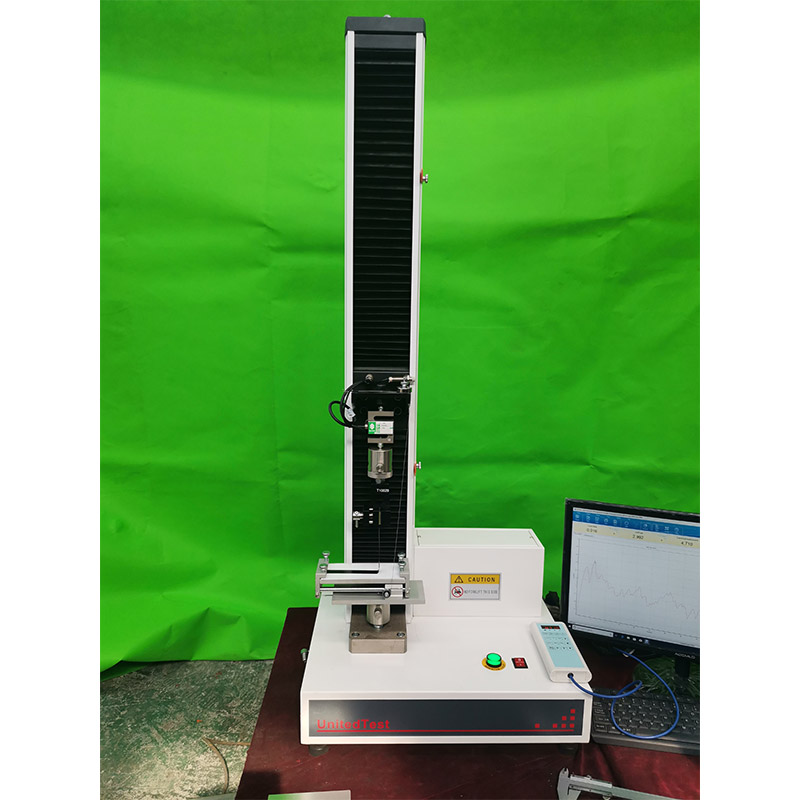

This adhesive 90-degree peel testing machine is widely used for mechanical property tests such as tensile, compressive, and tensile bonding strength of metal and non-metal materials, and is equipped with corresponding tensile and compression accessories.

Basic Information

Model: WDW-10

Resolution: 0.01

Measurement Accuracy: Class 1

Item Number: 465

Custom Processing: Yes

Power Supply Voltage: 220V

Specification: WDW-10

Weight: 150kg

Measurement Range: 0 - 1kn

Overall Dimensions: 910*465*1250mm

This adhesive 90-degree peel testing machine is widely used for mechanical property tests such as tensile, compressive, and tensile bonding strength of metal and non-metal materials, and is equipped with corresponding tensile and compression accessories.

Technical Specifications:

1. Test Machine Grade: Grade 1

2. Test Force Indicators:

Maximum Value: 1kN

Test Force Measurement Range: 1% ~

Test Force Accuracy: Better than ±1% of the indicated value

3. Deformation Indicators:

Deformation Measurement Range: 1% ~

Deformation Measurement Accuracy: Better than ±1% of the indicated value

4. Displacement:

Relative Error of Crossbeam Displacement Indication: ±1%

Displacement Resolution: 0.001mm

5. Speed:

Speed Range: 0.005mm/min ~ 500mm/min, stepless speed adjustment

Relative Error of Crossbeam Speed: Better than ±1% of the indicated value

Test Procedure for 90° Peel Test Machine of Adhesive:

1. Sample Selection

Apply a thin layer of the mixed adhesive on the concrete slab with a straight edge, then apply a thick layer. Use a toothed comb with 6mm*6mm depressions and a center spacing of 12mm for combing. The toothed comb should be inclined at approximately 60° to the base material and perpendicular to one side of the base material, and then be dragged parallel to the other end of the concrete. After 5 minutes, place at least ten test bricks on the adhesive, with a 50mm interval between each, and place (20±0.05)N pressure blocks on each test brick, maintaining for 30 seconds.

2. Tensile Bond Strength

After the prepared specimens are cured under standard test conditions for 27 days, attach the pull-out head to the test brick with an appropriate high-strength adhesive.

Continue to place under standard test conditions for 24 hours, apply tension at a speed of (250±50)N/s, and measure the tensile bond strength.

Record the test results, with the unit being N.

3. Tensile Bond Strength after Immersion in Water

After the prepared specimens are cured under standard test conditions for 7 days, immerse them in water at (23+2)℃.

After 20 days of immersion, remove the specimens from the water, wipe them with a cloth, attach the pull-out head to the test brick with an appropriate high-strength adhesive, and place the specimens under standard test conditions for 7 hours before immersing them in water at (23+2)℃.

After removing the specimens from the water, immediately apply tension at a speed of (250±50)N/s, and measure the tensile bond strength.

Record the test results, with the unit being N.

Contact Us

Adhesive Stripping 90 Degree Stripping Testing Machine

Adhesive Stripping 90 Degree Stripping Testing Machine

Wire Twisting And Winding Integrated Machine

Wire Twisting And Winding Integrated Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

NDS-10 Digital Display Metal Material Torsion Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

WDW-1 Microcomputer Controlled Electronic Universal Testing Machine

CPU-1020 Cup Convex Testing Machine

CPU-1020 Cup Convex Testing Machine

Impact Testing Machine For Metal Samples

Impact Testing Machine For Metal Samples