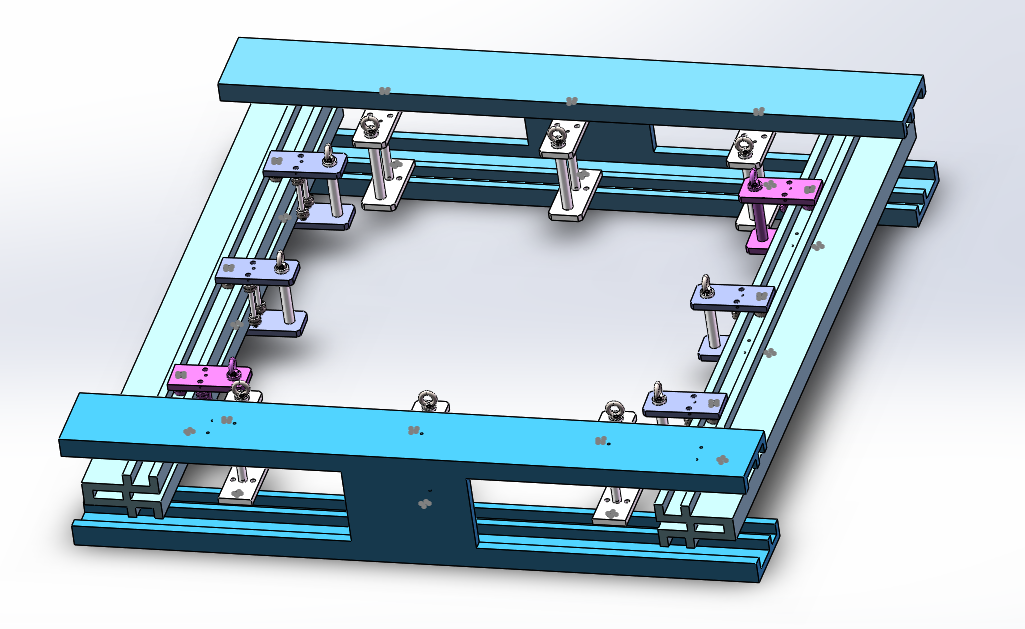

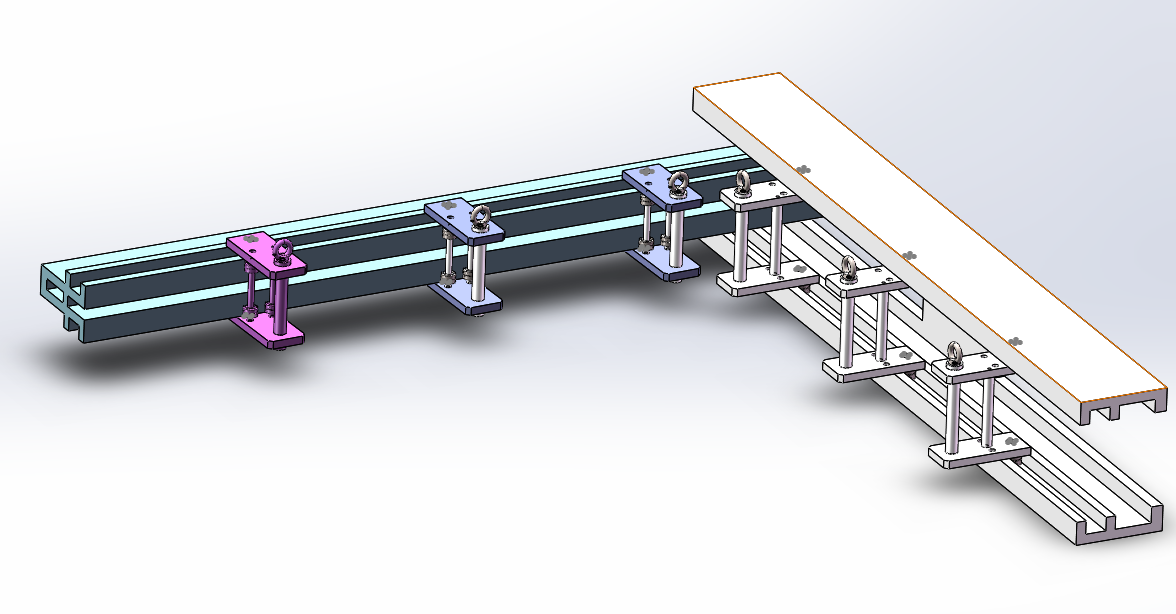

The four tensile main beams are cross-arranged, and two sets of guide rails are arranged under each tensile beam respectively, which play the function of guiding and anti-turning during stretching.

1. Product introduction

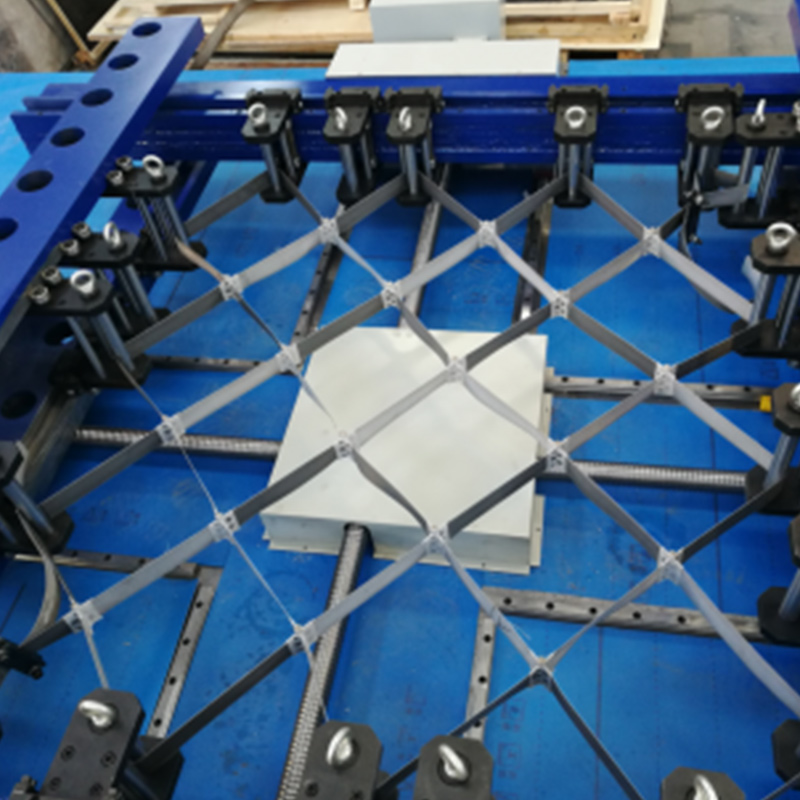

Host photo

Host photo

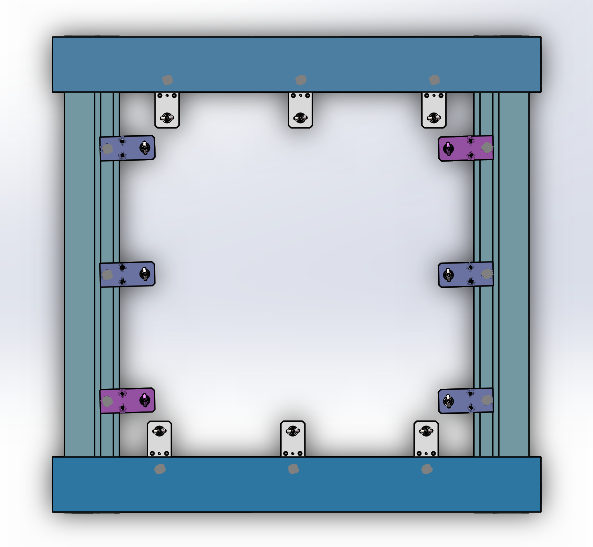

Schematic drawing

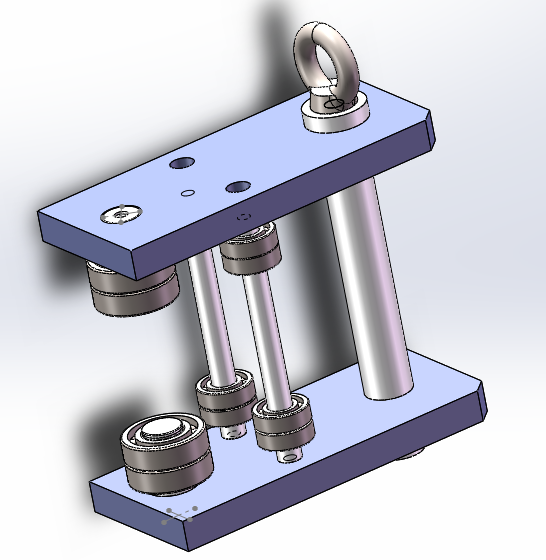

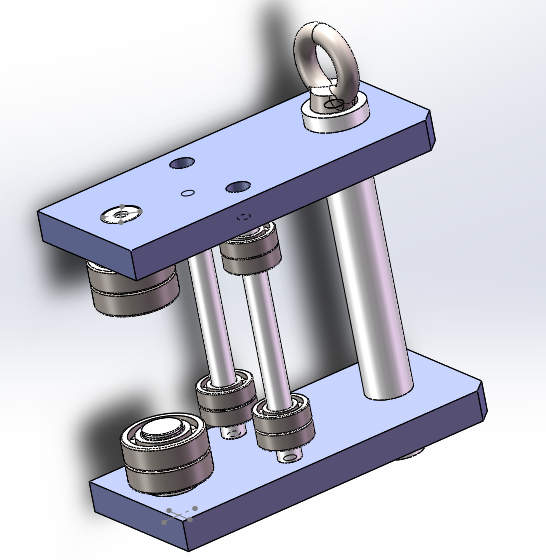

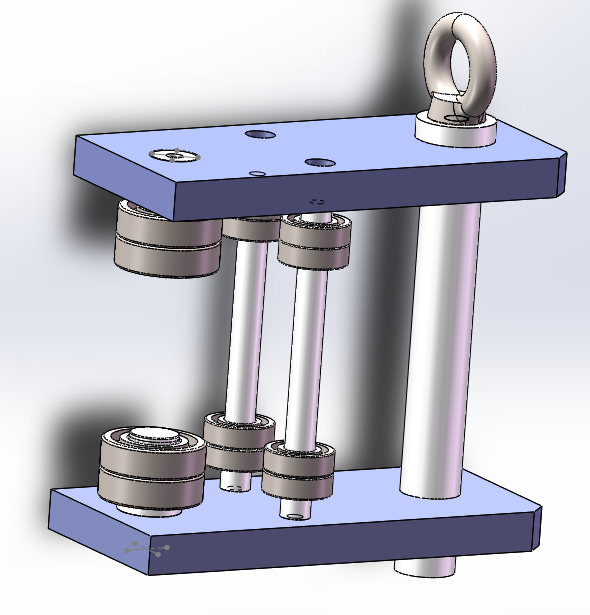

Three sets of bearing guide auxiliary retractor (tooling diagram)

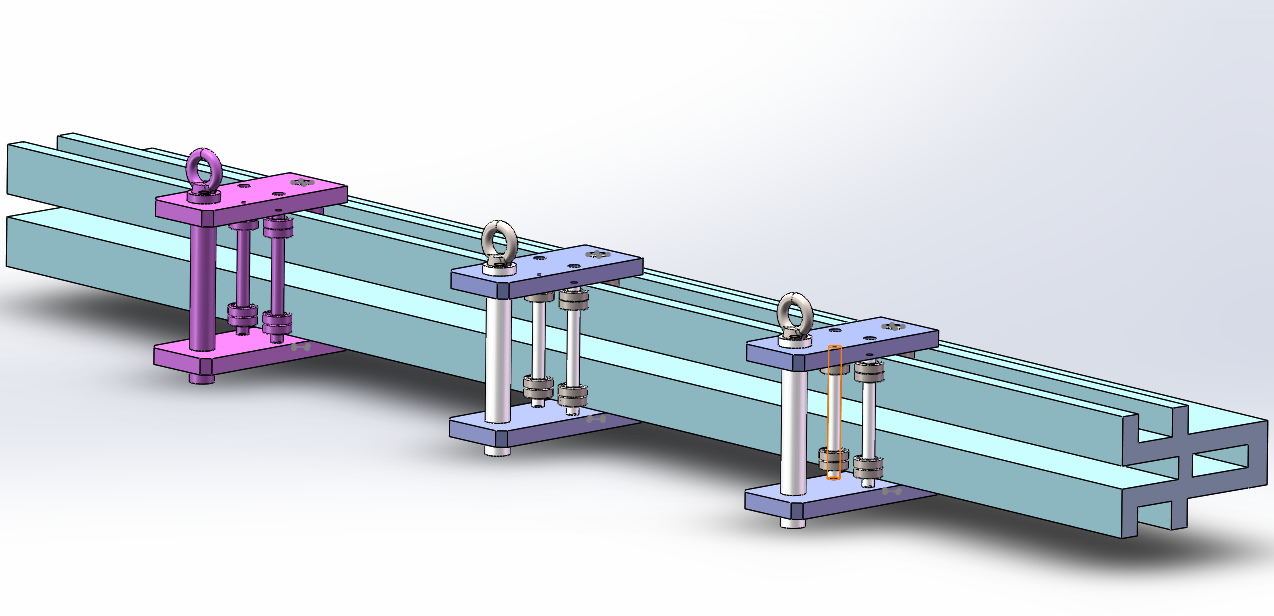

Beam and drawing tool assembly (diagram)

2. Function Description

As shown in the attached figure, the bidirectional tensile testing machine is used to test the mechanical properties of the node and the base material under the four-axis tensile state of the cell, wherein: the two axes move and the other two axes are relatively fixed (the fixed end has the central position adjustable and has the locking function, and the relative position is adjusted according to the different size of the cell, and the center point is inconvenient). The four tensile main beams are cross-arranged, and two sets of guide rails are arranged under each tensile beam respectively, which play the function of guiding and anti-turning during stretching. The active beam moves synchronously, and under the action of the cell component force, the guide rail groove of the main beam is driven by the tensile tool strictly, and three sets of constraint bearings are distributed below the tensile tool, as shown in the figure:

The test process can be dual-axis loading or single-axis loading, and the two are independently controlled without interfering with each other.

At the beginning of the design of the test system, refer to the existing cell forms in the market, and the tensile tooling can be interchanged to meet the tensile test of closed and open cell.

The product has been improved on the original basis, and the stretching tool at the starting end of the cell can ensure that the node at the starting end is not in the most powerful position when stretching.

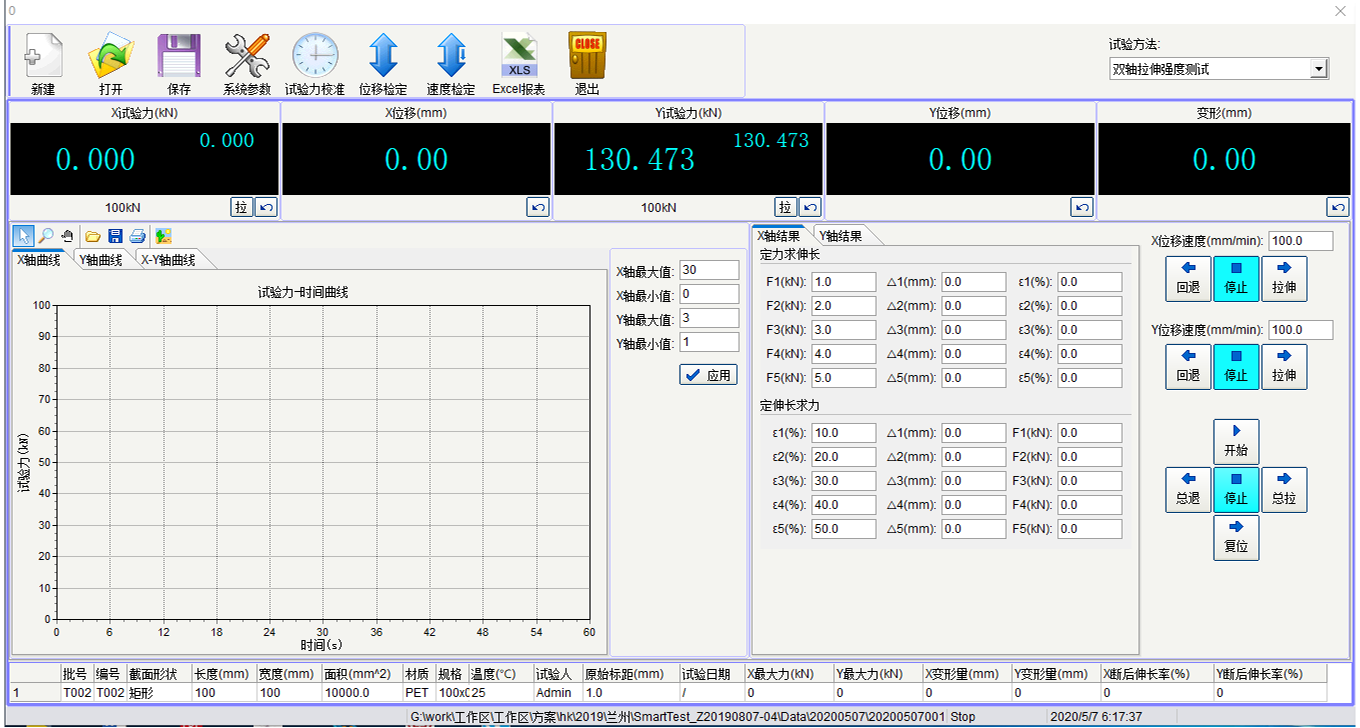

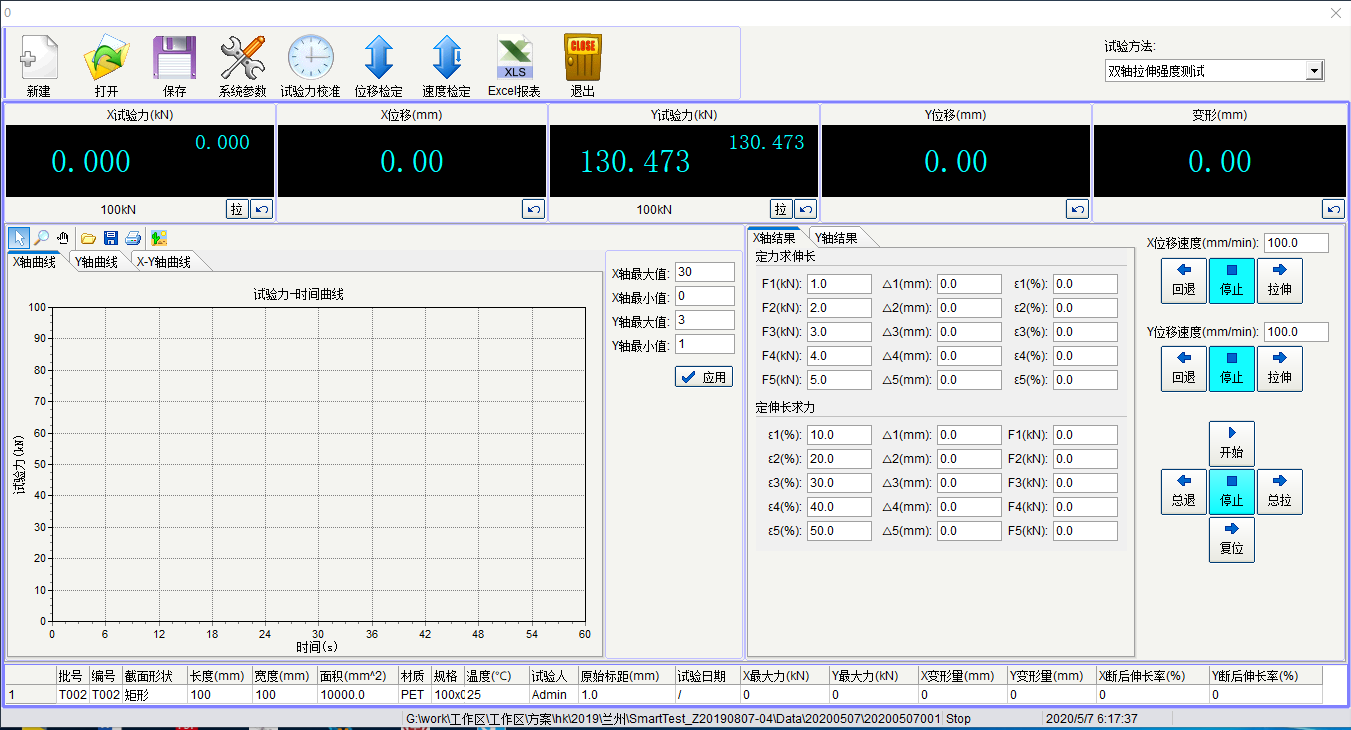

3. Software introduction

1.SupTest is a professional customized measurement and control software, which includes the test means and data processing methods required in the standard.

2. The database adopts ACCESS format, which is convenient to carry and expand. The data can be exported in real time and the original data can be extracted

3. At the same time, it can display three channels of acquisition in real time, and can be switched arbitrarily; In addition, the three-way calculation speed is displayed

4. During the test, multiple curves of XY axis can be displayed at the same time, and the coordinates that need to be displayed can be set, such as: load-time, load-displacement, stress-strain and other curves, and the coordinate full degree can be automatically adjusted.

5. The completed test can be re-read, the test curve can be enlarged, reduced, translated, and the feature position can be displayed and marked. The test parameters can be modified afterwards, the position of the feature points can be forcibly specified, and the modified results can be recalculated or restored.

6. Well support user-defined Excel reports, each test can support multiple user-defined reports, support the curve of test analysis output to user-defined reports

7. You can easily add new test standard library, you can easily add tests on existing standards, you can set different input and output items for each test, you can also set different report formats for each test, and multiple custom reports.

8. The loading process of the test can be set on the basis of the existing test, and the setting of the test steps is flexible and easy to understand.

4. The design, manufacture and inspection of the testing machine are in accordance with the relevant provisions of the following standards

1.GB/T2611-2007 "General Technical Requirements for Testing Machines"

2.JJF1103-2003 "Universal Testing Machine Computer Data Acquisition System Evaluation"

3.JJG139-1999 "Tensile, pressure and universal testing machine verification Regulations"

4.GB/T19274-2003 "Geosynthetic materials plastic Geoglass"

5.GB/T19274-xxxx "Geosynthetics Plastic Geoglespaces"

5. Electrical system:

(1) AC servo drive and AC servo motor, stable and reliable performance, with overcurrent, overvoltage, overspeed, overload and other protection devices. Speed ratio up to 1:100,000.

(2) With overload, overcurrent, overvoltage, displacement up and down limits and emergency stop and other protection functions.

(3) The electrical control circuit refers to international standards, meets the national testing machine electrical standards, and has strong anti-interference ability to ensure the stability of the controller and the accuracy of the experimental data.

Control system:

The fully digital closed-loop measurement and control system independently developed by our company has many advanced characteristics and technological innovations, mainly reflected in:

1. Realized four kinds of closed-loop control of test force, specimen deformation, displacement and test process;

2. The data acquisition system consists of 4 high-precision 24-bit A/D conversion channels. The highest resolution is 1/300000, the whole process is not divided;

3. Choose BB, AD, Xilinx and other original brand integrated devices, all digital design;

4. In line with PCI bus standards, microcomputer automatic identification and installation, so as to "plug and test";

5. Electronic measurement system without analog components such as potentiometers, to ensure interchangeability, easy maintenance and replacement

6. Technical parameters

1. The whole machine indicators

| Serial Number | Test Item | Technical requirements |

| 1 | Max testing machine | 100KN (dual channel) |

| 2 | test force resolution | 1/300000 ungraded throughout |

| 3 | The relative error of force value indication | ±0.5% in the range of 1%-100% |

| 4 | Deformation measurement range | 0.2% ~ 100%FS |

| 5 | Deformation resolution | 1/300000 ungraded throughout |

| 6 | Deformation indication error | better than ±0.5% |

| 7 | The relative error of zero point of test force | ±0.1% |

| 8 | Displacement resolution | 0.025mm |

| 9 | Force control rate adjustment range | 0.005 ~ 5%FS/s |

| 10 | Force control rate control accuracy |

rate < 0.05%FS/s, within ±2% of the set value; When the rate is ≥0.05%FS/s, it is within ±1% of the set value. |

| 11 | Deformation rate adjustment range | 0.005 ~ 5%FS/s |

| 12 | deformation rate control accuracy | rate <0.05%FS/s, it is within ±2% of the set value;When the rate is ≥0.05%FS/s, it is within ±1% of the set value |

| 13 | Displacement rate adjustment range | 0.001 ~ 500mm/min |

| 14 | displacement rate control accuracy | rate i<0.5mm/min, it is within ±1% of the set value;When the speed is ≥0.5mm/min, it is within ±0.5% of the set value |

| 15 | Constant force, constant deformation, constant displacement control range | 0.4%-----100%FS |

| 16 | Maximum beam movement distance | 1500mm (tentative) |

| 17 | Effective test span | 25000mm (tentative) |

| 18 | Beam travel | 1100mm |

| 19 | Dimensions (L x H x W) | 3800x3800x800mm |

| 20 | Power supply voltage (must be reliably grounded) | ~220V±10% 50Hz |

| 21 | weight of the machine | 4500kg |

7. System configuration list

| Serial Number | Name | Specification | Quantity | Remarks |

| 1 | Bidirectional frame rack | 3800x3800 | 1 set | company production |

| 2 | Workbench | 3800x3800 | 1 set | company production |

| 3 | Traction girder | 350x2200 | 2 set | company production |

| 4 | Traction trabecula | 200x2200 | 2 set | company production |

| 5 | Linear guide | HGH30 | 8 sets | TBI |

| 6 | Ball screw | FU5010 | 4 sets | TBI |

| 7 | Servo motor and driver | MGMH1322 | 2 sets | Japan Panasonic |

| 8 | Manual adjustment assembly | 2 sets | ||

| 9 | Force sensor | PSD-10SJ | 2 sets | American World Bolt |

| 10 | Measurement and control board card and software | ET813A | 2 sets | company production |

| 11 | Control cabinet | T1200 | 1 set | |

| 12 | Random technical file | 1 set | ||

| 13 | Random Number cables | some | ||

| 14 | Others tooling | some | ||

| 15 | Stretch tooling | 12 sets |

8. After-sales service

1. The warranty period is one year from the acceptance, lifelong maintenance, free service within one year, free on-site installation and commissioning of new machines, free training of operators.

2. The test equipment provided is in line with the current national standard or industry standard to ensure the technical advancement and reliability of the test equipment.

3. The required parts and accessories are supplied all year round.

4. Product perennial technical support, product maintenance within 24 hours to provide solutions, if need on-site solution within 48 hours to arrive. 4 Software lifetime free upgrade.

Large view of the software interface