The equipment can complete the whole process curve test of uniaxial compression of rock (soft rock) at normal temperature.

1. Technical requirements

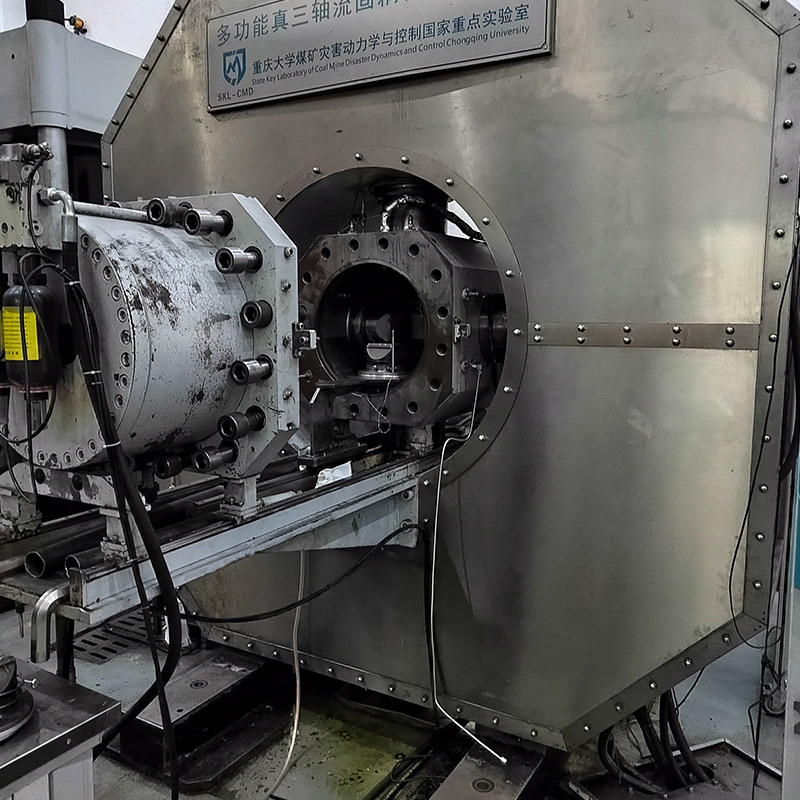

The equipment can complete the whole process curve test of uniaxial compression of rock (soft rock) at normal temperature. Complete the curve test of the whole process of triaxial compression of rock (soft rock) under high temperature environment. The acoustic emission test can be completed in the uniaxial triaxial environment, and the pore water seepage test of rock (soft rock) can be completed at room temperature and high temperature. Rock uniaxial compressive strength test (constant stress, constant strain, constant stress rate, constant strain rate, constant displacement rate, one-way cycle loading, load holding, unloading and other multi-link program control test). The measuring system has zero adjustment, calibration, continuous whole measurement without classification, and curve coordinate has adaptive row. Test force, deformation, displacement and other speed control and maintain, with overload automatic protection function, when axial deformation, radial deformation, time and other parameters reach the limit value or pre-set, sample fracture, oil circuit blocking and oil temperature is too high can be automatically protected. Stepless speed regulation, force, displacement, axial and radial deformation, various control methods can be smoothly switched curves, data storage and curve amplification during the test, and can be switched to display each test curve during the test. Automatic measurement, control, data acquisition, processing, curve drawing and calculation of compressive strength, confining pressure, axial deformation, radial deformation, Poisson's ratio, elastic modulus, etc.

2. Technical parameters

The system is mainly composed of axial and static load control system, confining pressure loading system, pore pressure seepage system, high temperature system and acoustic emission system. Sample size 50mm in diameter and 100mm in height; Diameter 75mm, height 150mm;

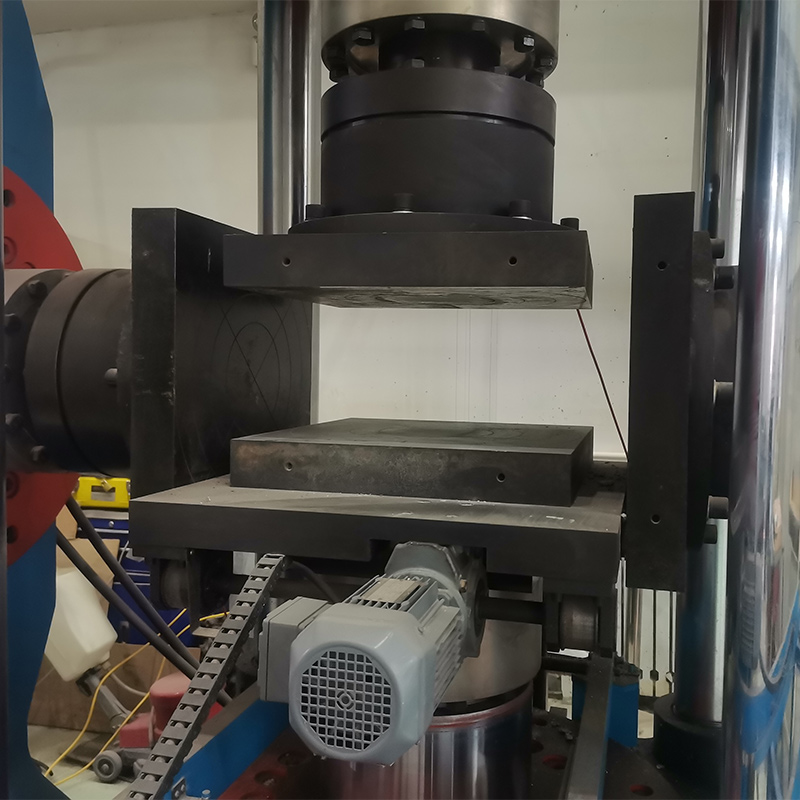

2.1 The rigidity of the main frame (200 tons frame) for axial compression loading is ≥10GN/m, and it is composed of monolithic cast portal frame, cylinder piston assembly (loading cylinder), pressure plate, etc. The loading cylinder is fixed on the lower beam, and the piston exerts test force on the sample upward; This structure maximizes the stiffness of the testing machine, reduces the gap of the testing machine, and also makes the appearance of the testing machine beautiful.

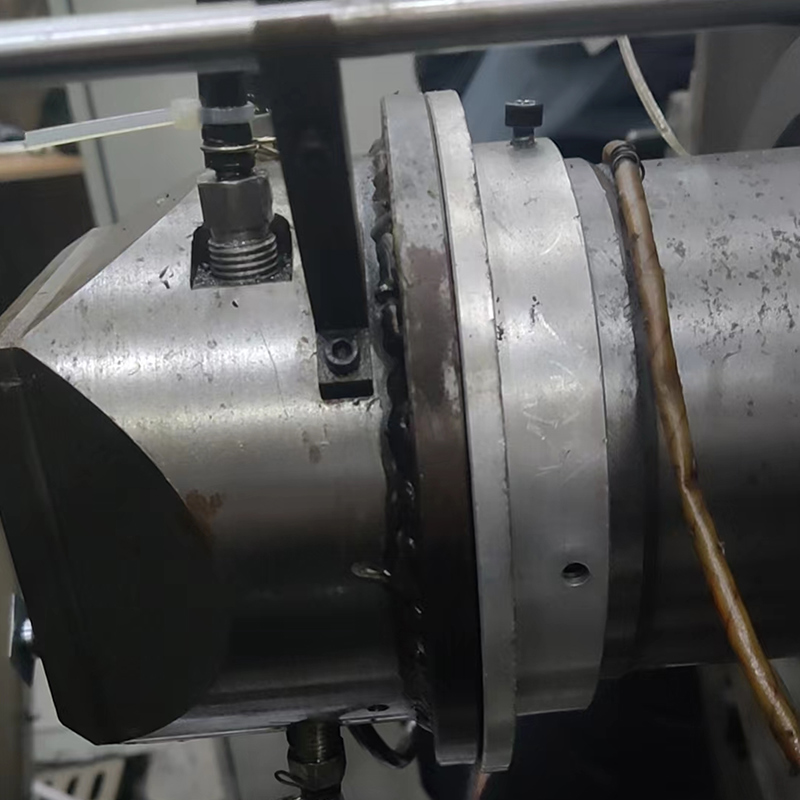

2.1.1 Integrated automatic lifting and lowering pressure explosion-proof pressure chamber, providing detailed description of pressure chamber explosion-proof technical solutions, no need to screw bolts or clamps; The pressure chamber can withstand no less than 100MPa. At the same time, the pressure chamber sensor lead is not less than 18 cores. The pressure chamber refueling and oil discharge are all operated by computer, without manually twisting the valve.

2.2, the maximum axial dynamic and static load test force is 200KN-2000kN, the effective force measurement range is 20kN-2000kN, the frequency is 0.01-5Hz, the force measurement accuracy is ≤±0.5%, the test force loading speed range is 0.01-20KN/s.

2.3 The confining pressure loading system is composed of a three-axis pressure chamber with self-balancing structure. The maximum confining pressure is ≥80Mpa, the confining pressure measurement accuracy is ≤±0.5%FS, and the confining pressure resolution is ≤0.02MPa. Confining pressure loading speed range 0.001 ~ 0.1Mpa/s.

2.4 Pore pressure seepage system: maximum pore water pressure: ≥80MPa, pressure range: measured within 2% to 100% of the maximum test force, accuracy: ≦±0.5%FS, resolution: ≤0.02MPa, water storage: ≥800ml; The maximum pressure of gas seepage is 25MPa, and the resolution is less than 0.01MPa.

2.5 High and low temperature system: The high temperature system is composed of heater temperature control meter, pressure chamber temperature control meter, heating circuit board, circuit breaker, heater, power switch, heating indicator light, ammeter, heating switch, etc., temperature range: room temperature -70℃ ~ 200℃, temperature resolution: ≤0.1℃, temperature control accuracy: ±1℃.

2.6 Acoustic emission system: equipped with at least 8 high temperature and high pressure sound transmitter sensors, resonant frequency 50KHz, size 18*18mm, supporting low noise signal lines;

(1) Acoustic emission sampling accuracy: 24-bit A/D accuracy, sampling rate: 2.5Msps, number of acoustic emission channels: 8;

(2) Acoustic emission signal characterization: characteristic parameters, acoustic emission waveform, original waveform flow;

(3) Acoustic emission characteristic parameters: arrival time, threshold, rise time, amplitude, duration, energy, ringing count, average frequency, peak frequency, RMS, ASL, duration, damping, etc.

(4) Preamplifier: built-in;

(5) Bus interface: Gigabit Ethernet;

(6) Local storage: data is stored locally on the computer, the size depends on the computer hard disk;

(7) External 220V power supply;

(8) Acoustic emission system software, perfect support for dual-core and multi-core processors, - enhanced interactive graphical interface for real-time acoustic emission signal acquisition/analysis, including: - for display/storage/playback under 16 channels; Multi-parameter analysis (figure); - Correlation analysis (figure); - Point/line/square (column) chart analysis; - Short-time FFT chart display analysis; - Spectrum diagram display analysis; - Output parameter results and waveform results in ASCII format; - Statistical analysis function of various acoustic emission parameters; Achieve full waveform acoustic emission signal acquisition, display, storage, playback, can achieve acoustic emission amplitude, ringing count, rise time, arrival time, energy, duration, rise time, ASL, RMS, peak count, vibration damping, external parameters and many other characteristic parameters, can be set up to 22 waveform charts, parameter tables. The waveform chart and parameter table can be correlated with each other. It also has rich analysis functions for the stored format files, providing open format for the analyzed data files, parameter data can be imported into excel, waveform data provides open text format for subsequent analysis with matlab.

The stored format file has rich analysis functions, and the waveform data is provided in an open text format for subsequent analysis with matlab.

2.7 Extensometer Round sample extensometer: axial deformation 0 ~ 10mm, radial deformation 0 ~ 5mm, measurement resolution ≤0.001mm measurement accuracy ±0.1% FS, the number of at least 3. (vertical 2, ring 1);

2.8 The displacement sensor has a measuring range of 0-100mm, mainly measuring axial cylinder displacement, booster cylinder displacement and hole pressure displacement. Measurement accuracy <±0.1%FS Measurement resolution ≤ 0.001mm, the number of 3.

2.9 Main Controller (one set)

1) Load, cylinder displacement, axial and circumferential extenometers can be used in the test process for combined multi-rate and multi-target quantity, without impact complex path control;

2) Adopt up and down machine mode, non-PC onboard controller; To ensure the same time-domain, it is forbidden to use multiple controllers in parallel. The controller has a quad-core CPU frequency of 1.6GHz; Memory 2GB; 4GB storage; High-speed USB2.0 interface; Dual Ethernet 1Gbps communication rate adaptive RJ45 network interface; It has 2 serial ports, of which 1 serial port is connected to the oil source PLC communication, setting its control pressure and flow. The controller can be directly connected to the U disk, and the data can be directly stored in the external device of the controller; The data can also be stored on the PC at the same time. Double data insurance to prevent data loss after computer crash and shutdown, so as to ensure data integrity and security.

3) Controller with main pressure, confining pressure, seepage, temperature 4 channels closed-loop control rate at the same time 20KHz; Software maximum synchronous 20KHz data acquisition and storage. The software can arbitrarily select several paths according to the actual number of connections to collect and save.

4) The controller has a manual speed handle to adjust the position of the cylinder, has the function of lifting and lifting, and has two speed adjustable, which is convenient for the installation of the specimen, and can be switched to control three cylinders respectively.

5) Static control accuracy 0.2%, dynamic control accuracy 0.5% (10% fs-100% FS). Phase control accuracy ±1°.

2.10 Computer and data processing software

1) Microcomputer system, configuration content is not less than: (INTEL i7-13700K CPU /32G-DDR4-3200 memory /1TSSD hard disk /NVIDIA Tesla V100-16GB)1.

2) The software has the function of programmable test path (the software is composed of four command stages: ramp, hold, dynamic, and sweep), and one or more cylinders can be arbitrarily configured for a combined test. For example, a test of main pressure first uses displacement loading, then switches to stress loading, then switches to axial strain control, and finally switches to circumferential strain control after failure; The confining pressure can be loaded first, and then switched to displacement loading, and when either stage of the main pressure and confining pressure arrives, the main pressure can be automatically triggered, and the confining pressure (during the holding stage) will be carried out in the next stage, and the data saving rate of each command stage can be arbitrarily set (maximum 20KHz); After the compiled path is complete, the compiled path can be loaded repeatedly.

3) The axial strain can be selected either one of the two sensors or the average value of both as a feedback control function.

4) At the same time, the software has multiple triggering modes at each stage (slope, hold, dynamic, sweep), and different triggering modes can be selected at each stage; The axial channel has the function of no action, axial stress trigger, axial displacement trigger, axial strain trigger, circumferential strain trigger, stress decay trigger to the next stage, and has 11 trigger modes of axial stress stop, axial displacement stop, axial strain stop, circumferential strain stop and stress decay stop test.

5) During dynamic loading, the software can be stored continuously and at intervals according to the number of waveforms, and the peak and valley values of stress/displacement/strain in each cycle can be stored. The software can display all path phase parameters, while the software can highlight the current test phase parameters.

6) The software can automatically adjust the PID parameter function during dynamic and sweep loading, and can automatically compensate the waveform error and phase error without human intervention; Within the full frequency range (≤5Hz), the entire adjustment process can be completed within 2 seconds from the start to the completion of the adjustment (within the error range specified by the equipment) (the comparison between enabling and disabling automatic compensation should be provided during acceptance).

7) Data collection includes: There are 13 collection modes: linear time, logarithmic time, stress change, master cylinder displacement change, axial deformation 1 change, axial deformation 2 change, axial average deformation change, circumferential deformation 3 change, confining pressure change, confining cylinder displacement change, osmotic pressure change, impervious cylinder displacement and temperature change, and one of them can be set at will for collection in each control stage.

8) Complete uniaxial test, triaxial test, static and dynamic test, custom path test, etc.

9) Data processing has three modules: historical data viewing, static data processing and dynamic data processing; Historical data view: you can look back at the stored data, you can look back at one of the sections as needed, local zoom in and out, etc., and the horizontal and vertical coordinates of the curve can be arbitrarily switched to time, force, displacement, axial strain, diameter strain, etc. Static data processing: a certain section of the curve can be intercepted for data fitting (fitting methods include: least square method, minimum absolute residual, Bisquare three ways) to find the elastic modulus E, Poisson's ratio; At the same time, the modulus and Poisson's ratio at half of the maximum strength can be obtained. Dynamic data processing: can be viewed according to the cycle, can be specified to view the force and strain data under A certain week, can also be continuous from A to B cycle force and strain data; According to the specified period data, the current dynamic cycle, maximum stress, minimum stress, maximum strain, minimum strain, dynamic elastic modulus, dynamic Poisson's ratio, dynamic shear modulus, damping ratio coefficient can be calculated within each period.

2.11 The maximum oil source pressure is 23MPa, the hydraulic gear oil pump is adopted, the maximum flow rate is 60L/min, the pressure and flow are controlled by PLC, the flow and pressure can be set through the touch screen and the main controller serial port communication, the flow and pressure can be stepless adjustable from 15%-100%FS;

3. Main configuration

3.1 One set of axial compression system

3.2 One set of confining pressure system

3.3 One set of seepage system

3.4 One set of high temperature system

3.5 A set of acoustic emission system

3.6 One set of hydraulic system

3.7 One electric control system

3.8 Test two operating systems

3.9 One set of cooling system

3.10 A set of pneumatic system