Used to test the maximum torque, shear modulus of materials and components, specified non-proportional torsional strength, yield strength, upper and lower yield strength, maximum non-proportional shear strain and other mechanical characteristics, with the corresponding tooling can test torsional stiffness, torque coefficient, and other specific indicators.

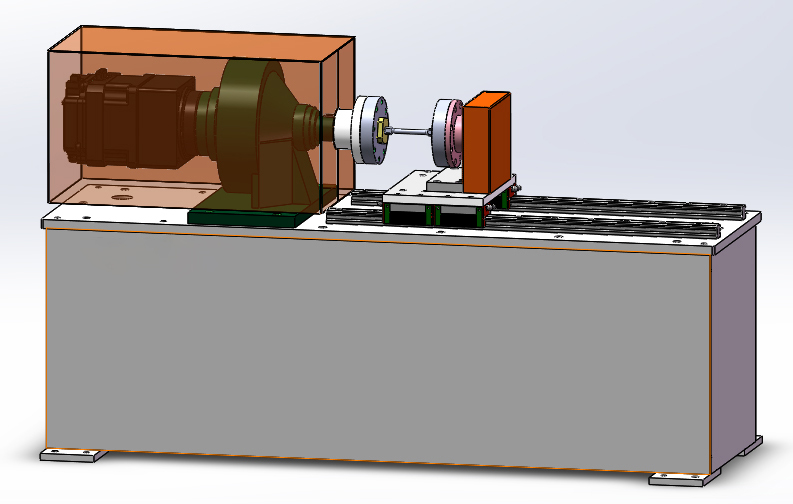

1. Nw-30 bone screw torsion testing machine picture

2. Product function: Used to test the maximum torque, shear modulus of materials and components, specified non-proportional torsional strength, yield strength, upper and lower yield strength, maximum non-proportional shear strain and other mechanical characteristics, with the corresponding tooling can test torsional stiffness, torque coefficient, and other specific indicators.

3. Meet and reference standards:

1.GB/T2611-2007 "General Technical Requirements for Testing Machines"

2.GB/T10128-1998/2007 "Metal torsion test method at room temperature"

3.ISO7800-2003 Uniaxial torsion test method for metal materials

4.ASTM A 938-2004 Test method for torsion of wire

5.ASTM A938-07 Test method for wire torsion test

4. Product composition and characteristics

Features:

Torsion testing machine combined with foreign advanced control technology, exquisite appearance design. The high strength host is composed of high precision ultra-wide linear guide rail and ultra-thick host steel plate, and the AC servo motor is used as the output power source to transmit to the high efficiency cycloidal pinwheel deceleration system to realize the high performance torque and torsion Angle output and control.

The control system adopts the world's popular high-speed PCIE standard parallel bus design, adopts the American BB amplifier, AD company's high-speed analog-to-digital converter and CPLD to form the data acquisition system and high-precision torque sensor to form the measurement control system. The controller CAN be extended to support communication methods such as LAN USB CAN.

The professional software of the testing machine can automatically obtain the maximum torque, torsional strength, upper and lower yield torque, specified non-proportional torque, shear modulus and other data and indicators. The control and data processing of the test process by the computer control system meet the requirements of the corresponding international standards. word, open database MDB and original data source txt form no pollution, low noise, high efficiency, with a wide speed range. This machine is suitable for all kinds of metal, non-metal and composite material mechanical properties index test, fully meet the requirements of the relevant national standards.

5. Structure composition:

1. Load the unit:

1) The planetary reducer is used as the deceleration unit to configure the servo motor loading, and the reducer is customized with zero back backlash structure, which can ensure that there is no system gap during the torsion process, and low cycle fatigue can be carried out in addition to meeting the conventional static test. Zero crossing (the torque decreases from the maximum forward to zero during the middle process of reverse loading to the maximum). It can ensure the integrity of the curve and the accuracy of the data

2) High-strength alloy output shaft, servo control, two-way swing.

3) The servo motor is directly hard linked with the actuator to ensure that there is no gap during positive and negative rotation.

4) Bearing support. Protect against radial force.

5) High response servo motor as a power source to ensure the stability and continuity of torque output.

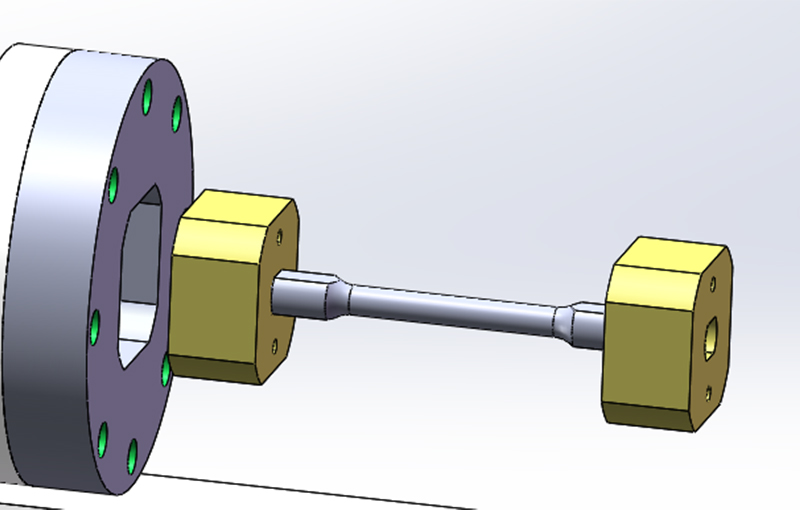

2. Fixture:

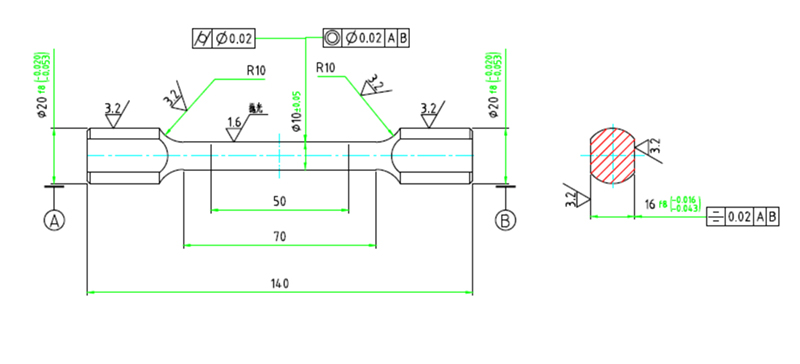

legend

Adopt standard mechanical interface, according to different diameter of the sample, processing matching pliers, pliers size is standard size, the equipment comes with sample processing size drawings, convenient for customers to process the sample.

The clamping material is carburized and quenched by 20CrMnTi, the hardness is not less than HRC 52, and can also be customized according to customer requirements.

3. Sensory unit

The strain type double flange torque sensor is used as the measurement sensor of torque, which is characterized by axial impact resistance, lateral force resistance and strong overload capacity. In principle, the characteristics of the parent material are still within the elastic range.

The inside of the sensor is a four-bridge structure, and the bridge and bridge are compensated accordingly to ensure the repeatability and sensitivity of the test process.

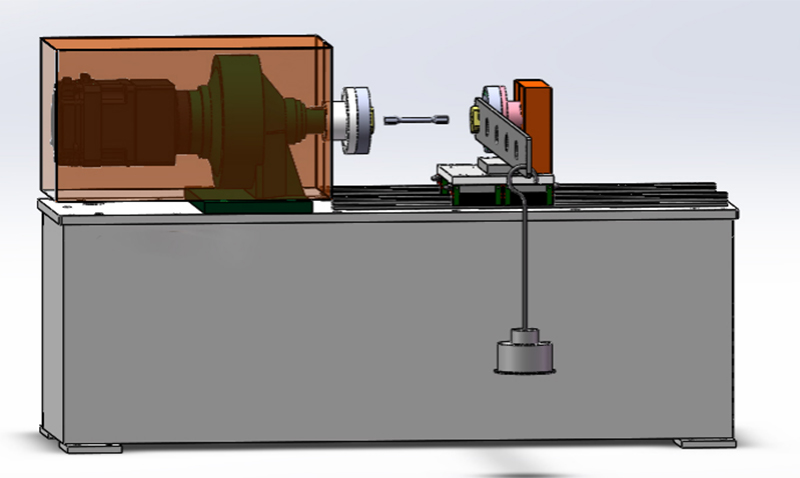

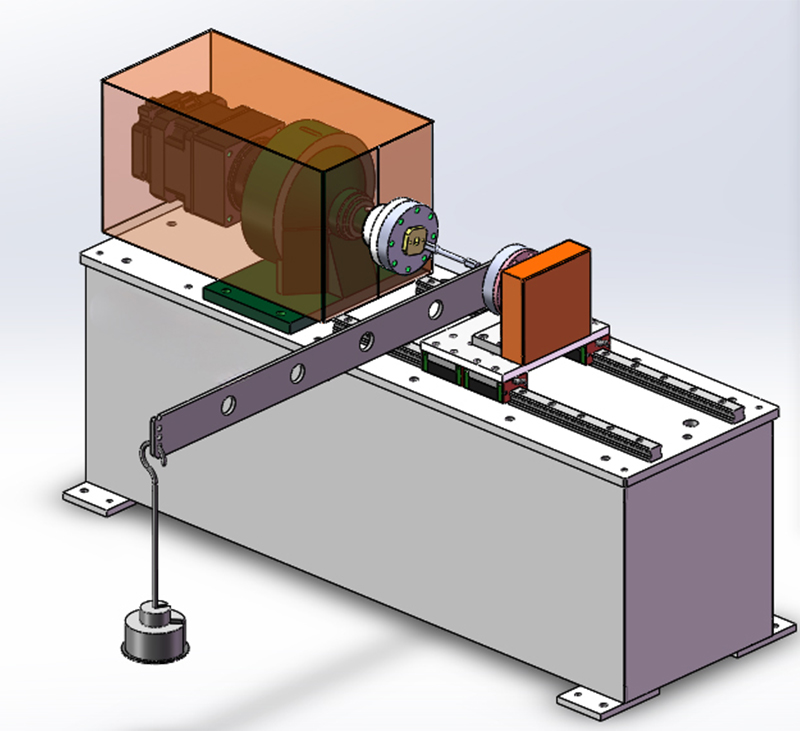

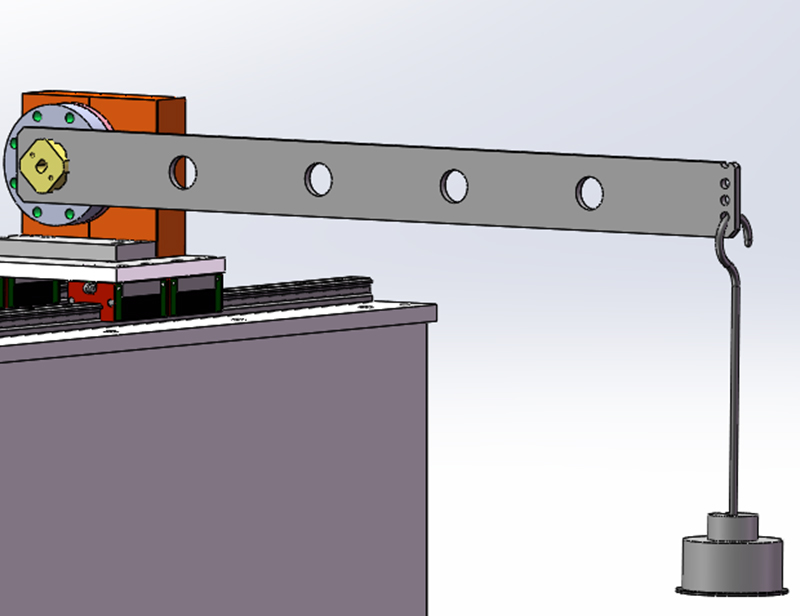

4. Calibrate the unit

The calibration principle T=F*L, where T is the target torque (unit: Nm), F is the weight weight (unit N), L is the length of the moment arm, the nominal length of the random calibration lever is 1000+0.1mm,(according to 1 when calculating). During calibration, fill in the calibration target value according to the above formula, load the corresponding weight, and click calibration to complete the calibration. For detailed operations, see the software instruction manual.

5. Software and measurement system

Hardware part:

The system consists of three signal conditioning units (torque unit, Angle unit, sample deformation unit), control signal generator unit, servo motor control unit, necessary I/O interface, software system, etc.

The closed-loop control loop of the system consists of measuring sensors (torque sensor, Angle sensor, deformation extensometer), servo motor, controller (each signal conditioning unit) and servo amplifier. DSP technology and neuron adaptive control algorithm are adopted to achieve full digital closed-loop control, and the most advanced PID professional control chip and multi-channel high-speed data acquisition and processing module are adopted. The mixed architecture of DSP+MCU is applied to the full digital three-closed-loop measurement control system, the resolution is not less than 1/350000FS, and the measurement process is not divided. It can realize a variety of closed-loop control modes such as constant rate test force, constant rate displacement and constant rate strain, and the control mode can be arbitrarily combined and smoothly switched.

With network interface, data networking and remote control can be realized.

| Function Item | Technical Index | Application |

| Torque measurement | Sampling frequency: 30Hz/120Hz; Resolution: 3*10ˉ6FS | Force, torque and other measurement |

| Deformation measurement | Sampling frequency: 30Hz/120Hz; Resolution: 3*10ˉ6FS | torque meter |

| Displacement measurement | Capture frequency: 2MHz | servo motor position non-destructive measurement |

| Servo motor control | PWM control frequency: 2MHz | servo motor position control |

| Digital signal input | 2 Digitallnput | upper and lower limits |

| USB communication | USB2.0 specification, 480Mbps | and host computer communication |

| Remote | control distance: 5m; Object Password lock | Quick operation |

| Test-t Test software | equipment management, sample plan, test report, curve analysis | |

| Sampling frequency | 30Hz, 120Hz. The default value is 30Hz | |

| The signal bandwidth | 6Hz at the sampling frequency of 30Hz and 23Hz at the sampling frequency of 120Hz | |

| Resolution | 1/300000 of full scale | |

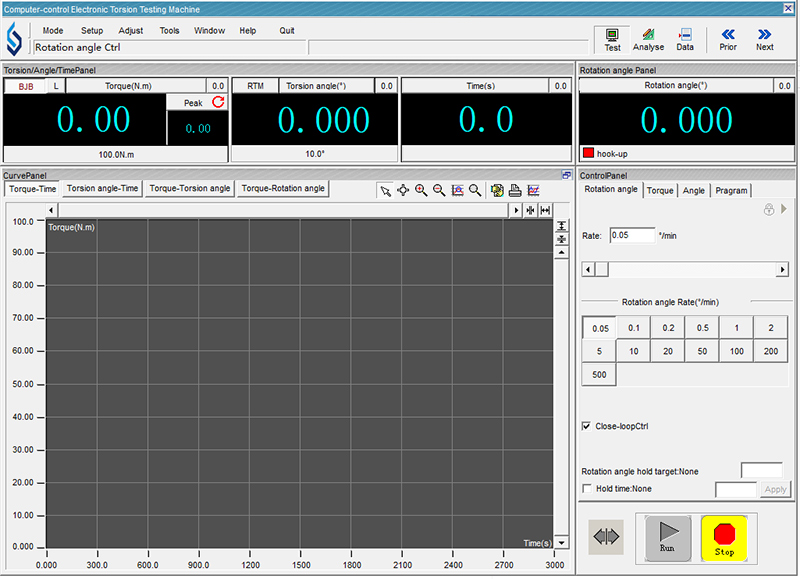

Software part:

Based on the Win7/10 operating platform, the software is simple to operate, powerful, human-machine dialogue structure. Easy to operate and learn

The software adopts modular design, different test types are created, test control and data analysis have independent modules, separate from the main program. It can adapt to various test types of test control and data processing

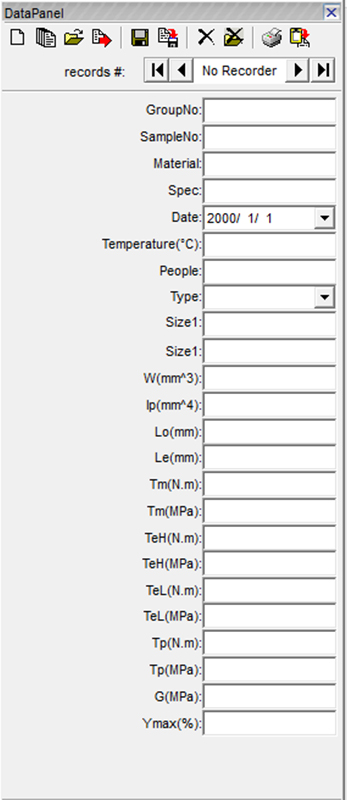

Test data can be added by the user, the number is not limited, using the template to create a new test record, convenient and fast

Automatically complete the test process, judge the broken type, and automatically record and save the test data. All test data are stored in the international XML format

The efficient test data management function can realize the fast query, loading and deletion of test data in various ways

At the end of the test, the system automatically analyzes and statistics the test results, and the analysis method can be set by the user

The flexible report editing function provides users with a special report editing tool for graphic typesetting, which is simple and easy to learn, and can easily print test curves and related pictures and text

Users can delete the test data according to their needs

Users can change the analysis method according to their needs, and the data can be modified according to their own needs

Dedicated database management library module

The test force value is displayed digitally in four grades, and the accuracy is ±1% of the value indicated at the beginning of 20% of the range of each grade

Divided into four digital display deformation, accuracy is 20% per range starting ±0.5%

Record torque-time, torque-angle, torque-angle, torque-angle test curve at the same time, can be switched at any time, zoom in and out, horizontal or vertical movement, real-time high-speed sampling

The man-machine interaction method is used to analyze and calculate the mechanical properties of the test materials. At the end of the test, the system will automatically calculate the maximum torque, torsional strength, upper and lower yield torque, specified non-proportional torque, shear modulus, etc. On the basis of automatic analysis, manual intervention can also correct the analysis results to improve the accuracy of the analysis

Provide a variety of report printing interfaces, users can edit reports in any format according to needs

Test data adopts standard database management, and automatically saves all test data and curves

Three closed-loop control software, interactive interface, convenient customer experimental operation and data processing

According to the needs of customers, the test can be completed after the basic sample information input, data automatically saved after the end, convenient data query mode, office, universal interface icon, easy to understand, convenient for non-professionals to query operations, the test software supports Temo mode, that is, the experiment computer and the data analysis computer can be separated, that is, data sharing. It is convenient for customers to analyze relevant data.

See the operation manual for more software information.

6. Main technical indicators

1. Maximum torque: 500Nm

2. Torque measurement range: 20N/ M-500N /m

3. Testing machine level: 0.5

4. Relative error of torque indication value: better than ± 1%

5. Torque resolution (Nm) : 0.002Nm

6. Torsion Angle measurement range: 0-10000°

7. Effective space: 10-300mm(customized according to customer samples)

8. Relative error of torsion Angle: ± 1.0%

9. Resolution of torsion Angle: 0.01°

10. Relative error of torsion Angle of torsion meter: ± 1.0%

11. Twisting speed :0.01°/ min-720 °/min

12. Relative error of torsion speed: within ± 1.0% of the set value

13. Software and user interface: Software and interactive human-computer dialogue operation interface in the WIN10 operating environment

14. The test process, measurement, display, analysis and control are automatically completed by the computer

15. After sample destruction, automata

16. When the load exceeds the rated value by 3 ~ 5%, automatic stop

17. Power supply: 220V, 50Hz, 1KW

7. Testing machine host configuration

High strength torsion testing machine host (bench structure, anti-corrosion treatment of the whole machine)

High precision Angle encoder (motor built-in)

Ac servo speed control system and AC current servo speed control motor each set

Two sets of precision linear guide rails

A set of high-efficiency needle-thread balance reducer

500Nm high-precision dynamic torque sensor

A set of special torsion AIDS for testing machine (meet the requirements of 2 samples)

Brand computer one

One color inkjet printer

Torsion testing machine special test and control system

WIN10

A set of special software for torsion testing machine under operating environment

8. Quality assurance

The equipment shall be deemed to have been officially delivered after being formally accepted by the ordering party. The three guarantee period of the equipment is one year from the date of formal delivery (except for the supplier's extension provisions). During the three guarantee period, the supplier will provide timely service and maintenance for all kinds of failures of the equipment. If the equipment fails during the use of the warranty period, the supplier will provide service to the customer in time and actively assist the customer to complete the maintenance task.

9. Acceptance and after-sales service:

1. After the equipment installation, commissioning and acceptance, the supplier shall provide free training to the operators on the operation and maintenance of the equipment

2, the equipment after the commissioning and acceptance, free warranty for 12 months, after the expiration of the warranty is responsible for long-term maintenance services.

3. After the installation and commissioning of the equipment is completed, the equipment shall be accepted according to the relevant international and national standards.

4, free long-term equipment consulting, commissioning services.

Optical Cable Junction Box, Electrical Box, Optical Cable Box Sealing Performance Testing Machine

Optical Cable Junction Box, Electrical Box, Optical Cable Box Sealing Performance Testing Machine

PDS1000 Fatigue Test System V3 For Orthopedics

PDS1000 Fatigue Test System V3 For Orthopedics

PDSN3030 Compression And Torsion Fatigue Testing Machine

PDSN3030 Compression And Torsion Fatigue Testing Machine

Dual Channel and Balance Bar Fatigue Testing Machine

Dual Channel and Balance Bar Fatigue Testing Machine

Tooth Material Reciprocating Friction Testing Machines

Tooth Material Reciprocating Friction Testing Machines

Rotary Bending Fatigue Testing Machine

Rotary Bending Fatigue Testing Machine